Pedro Lima

My interest in electric transportation is mostly political. I’m tired of coups and wars for oil. My expectation is that the adoption of electric transportation will be a factor for peace and democracy all over the world.

BYD’s fifth car factory in China is expected to start production on April 15 at Fuzhou city, Jiangxi province, with a planned annual production capacity of 200.000 vehicles.

This is especially good news since the Chinese automaker recently announced that is now producing BEVs (Battery Electric Vehicles) and PHEVs (Plug-in Hybrid Electric Vehicles) only.

Let’s see all the production bases of BYD (already operating and under construction).

Shenzhen (already operating) Xi’an (already operating) Changsha (already operating) Changzhou (already operating) Fuzhou (imminent start of operation) Hefei (under construction) Zhengzhou (under construction) Jinan (under construction) Xiangyang (under construction) As for global sales goals, if supply chain conditions improve, BYD expects to sell at least 2 million vehicles in 2022, which represents a solid increase from the previous year - when 320.810 BEVs and 272.935 PHEVs were sold.

Now with the official presentation, we have all the technical specs of the smart #1 all-electric SUV.

Let’s see them.

Drivetrain and Performance:

• Engine set up, drive train configuration: electric engine, rear-wheel drive • Performance: 200 kW (272 PS) • Max torque: 343 Nm • Max speed: 180 km/h (112 mph)

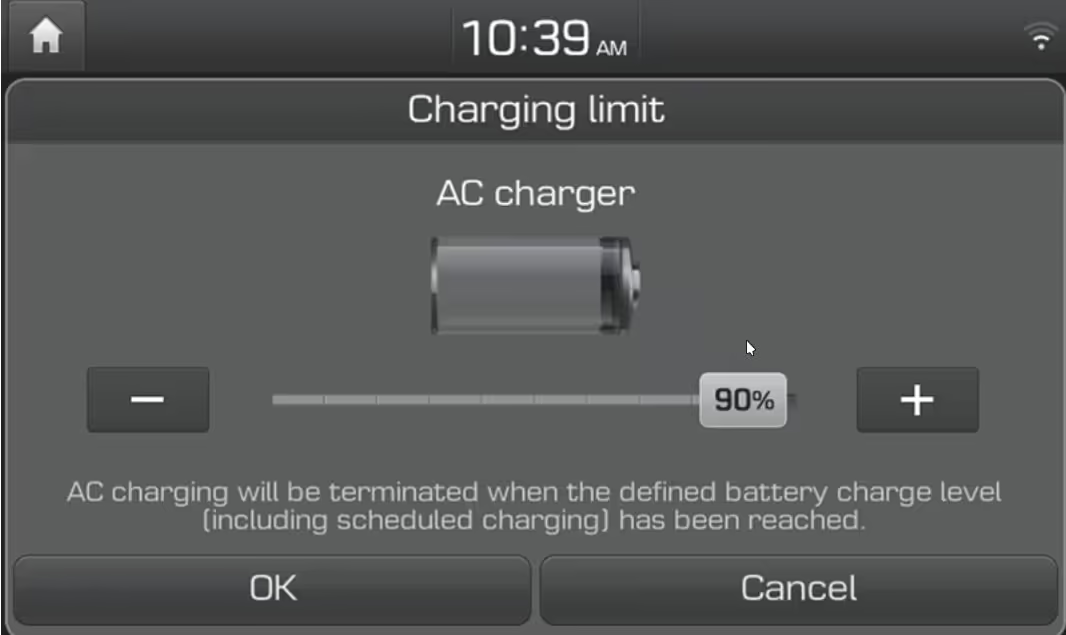

Charging and Consumption:

• Battery architecture and max capacity: NCM battery / 66 kWh • Max range WLTP: 420-440 km or 260-273 miles • Max charging capabilities: AC: 22 kW, DC: 150 kW • Charging times: AC: 10-80 % < 3h DC: 10-80 % < 30 mins • Usable connector types: CCS Type 2 Europe – Charging cable mode 3 standard • Available additional home charging solutions: smart wallbox in partnership with ABB, charging cable with home socket (Mode 2) as an accessory.

By the end of 2022, CATL will finally start producing battery cells in Europe (Germany). Machinery is already being installed.

Contemporary Amperex Technology Thuringia GmbH (CATT) is CATL’s first battery plant outside China and will have an initial annual production capacity of 8 GWh, but an increase to 14 GWh is already planned.

Notice that 8 GWh is enough for 160.000 EV battery packs of 50 kWh each, while 14 GWh is enough for 280.000. Not much, but it’s a start…

Gotion High-Tech, also known as Guoxuan, announced at the China EV100 Forum that the mass-production of its energy-dense LFP (LiPePO4) battery cells will finally start by the end of the year. Hopefully, this time is for real…

Let’s look at the initial plans and see what comes next.

Guoxuan’s LFP battery cell evolution

2009: 95 Wh/kg 2015: 140 Wh/kg 2019: 190 Wh/kg 2020: 212 Wh/kg (191 Wh/kg at pack level with JTM) 2021: 230 Wh/kg (207 Wh/kg at pack level with JTM) 2022: 260 Wh/kg (234 Wh/kg at pack level with JTM) Curiously, unlike its main competitors, CATL, BYD or SVOLT, Guoxuan will produce its energy-dense LFP battery cells in pouch format, instead of prismatic. Therefore, Guoxuan’s battery packs will use modules and the JTM (Jelly roll-to-module) technology to achieve an impressive GCTP (gravimetric cell-to-pack) ratio of 90 %, which is about the same we have in modern module-less packs with the CTP (cell-to-pack) technology.

Finally, SVOLT confirmed that it has reached this milestone and their battery cells are available for automakers to order.

Until sodium-ion batteries (NIBs) for electric vehicles become mass-produced in large scale, LFP (LiFePO4) is still the best cobalt-free battery chemistry widely available that allows electric cars to compete with their ICE (Internal Combustion Engine) alternatives, in price and availability.

Nowadays, any development in LFP battery technology is regarded as crucial to enable the massification of electric cars, therefore reaching an energy density of 200 Wh/kg has been a goal for a long, long time.

The world’s biggest battery maker, CATL, announced that its third-generation CTP (cell-to-pack) battery technology is ready for mass production and the official launch is expected in April.

Through continuous technological iteration, CATL has launched the third-generation CTP, which is called Qilin Battery internally. Its system weight, energy density and volumetric energy density continue to stay at the highest level of the industry. With the same chemical system and the same pack size, Qilin can deliver 13% more power than the 4680 battery.

SVOLT Energy now plans to reach a battery cell production capacity of 600 GWh by 2025 and become the world’s biggest producer.

Let’s see how does this figure compares to other major Chinese battery cell makers.

Expected production capacity by 2025

CATL: 520 GWh CALB: 500 GWh Guoxuan: 300 GWh BYD: 170 GWh (will be revised soon) Notice that 600 GWh is enough to produce 10 million battery packs of 60 kWh each or even 12 million if the capacity is 50 kWh. I think that a 60 kWh battery is the sweet spot for most efficient passenger electric cars that carry 5 people. On average 70 million cars are sold every year globally.

Right now SVOLT seems to be the only major battery cell maker that aims to provide a good alternative to the popular BYD Blade Battery, by introducing its own long prismatic cobalt-free battery cells to be used in simple module-less battery packs.

The prototype of the second generation SVOLT L600 short blade battery cell has the following specs:

Model: L600 (second gen) Capacity: 196 Ah (first generation was 184 Ah) Voltage: 3,2 V Energy: 627,2 Wh Gravimetric energy density: 185 Wh/kg Volumetric energy density: 430 Wh/L Chemistry: LFP (LiFePO4) Start of production: Q3 2022 By adopting a 100s1p configuration (100 cells in series), battery packs would have a capacity of 62,72 kWh. I think that 60 kWh is the sweet spot for affordable mainstream electric cars.

Hozon Auto is now launching the new NETA V Pro as a more affordable alternative to the popular BYD Dolphin.

Positioned as a 70,000-class smart technology cabin, Nezha V has delivered 40,372 units since its launch on November 3, 2020, becoming the top seller of pure electric SUVs among new car companies. With outstanding product highlights such as high-value, high-performance, and high-quality products, Nezha V has been deeply recognized by young consumers, especially in first- and second-tier cities that account for more than 50% of delivery.

After GAC, it’s now time for Xpeng to also announce its plans to build a fast charging network comprised of powerful 480 kW chargers, to fully take advantage of its upcoming 800-volt system platform.

As of September 30, Xpeng already counted with 439 fast charging stations in China.

Xpeng says that its upcoming electric cars built on a new super-efficient 800-volt platform will only require a 5 minutes charge to get enough energy to drive for 200 km.

Right now CATL is Tesla’s sole supplier of LFP (LiFePO4) battery cells, but BYD seems to be the next on the list.

According to Chinese media, Tesla has secured an initial order of 10 GWh worth of LFP battery cells from BYD, to power the Model 3 and Y in their standard range versions.

10 GWh is enough to assemble more than 181.000 battery packs for the Tesla Model 3 with 55 kWh each, or more than 166.000 for the Model Y with 60 kWh each.

The Leapmotor T03 is probably the best affordable small electric car currently being sold in China. Not only it has a decent 403 km NEDC range (around 300 km in WLTP), fast charging via CCS, OTA (over-the-air) updates, it’s also full of safety features that are extremely rare in its segment

Safety features that can prevent accidents, such as AEB (Automatic Braking System), LKA (Lane Keeping Assist), ACC (Adaptive Cruise Control) and a ADS (Automated Driving System) called Leap Pilot 2.0.