BYD Blade Battery is currently the best example of a good module-less and cobalt-free battery for electric vehicles.

When it was launched, the energy density was at 140 Wh/kg, then slowly increased to 150 Wh/kg.

Recently, BYD Chairman Wang Chuanfu revealed for the first time at a financial report communication meeting that BYD is currently developing a second-generation blade battery to be released as soon as August 2024.

This second generation CTP (cell-to-pack) battery from BYD will reach a gravimetric energy density of 190 Wh/kg, which suggests that at the cell level the density will be around 220 Wh/kg - considering a GCTP (gravimetric cell-to-pack) ratio of 85 %.

At this level of energy density, the cells are definitely LMFP.

Curiously, Gotion will also have its LMFP battery released this year with an energy density of 190 Wh/kg at the pack level.

As for BYD’s main competitor, CATL, is also expected to launch its LMFP battery soon with a gravimetric energy density of 210-230 Wh/kg and volumetric of 450-500 Wh/L at the cell level.

LMFP is basically an upgraded version of LFP (LiFePO4) with manganese added for increased voltage and energy density. With a 15-20 % higher voltage when compared to LFP, the problem until now was getting proper electrolyte and electrode coating to prevent extreme corrosion from occurring with charge/discharge cycles.

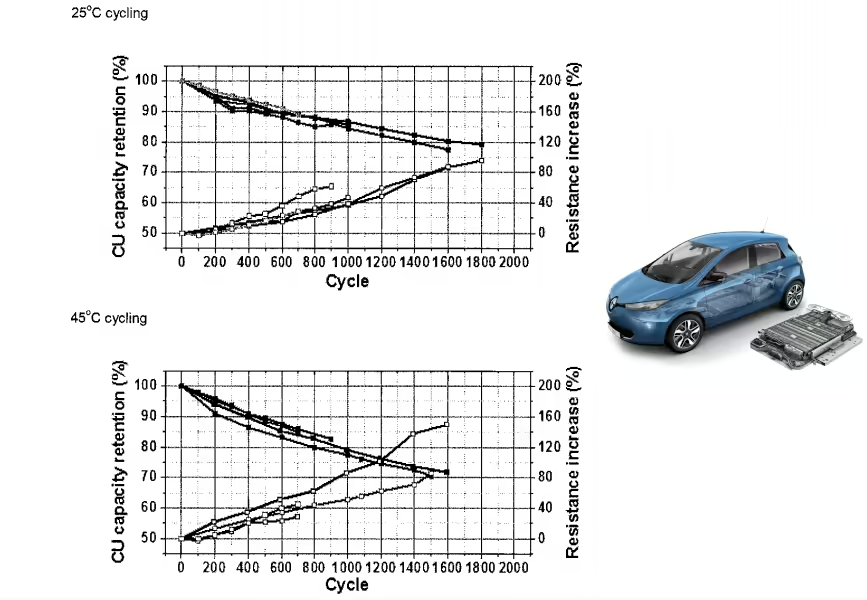

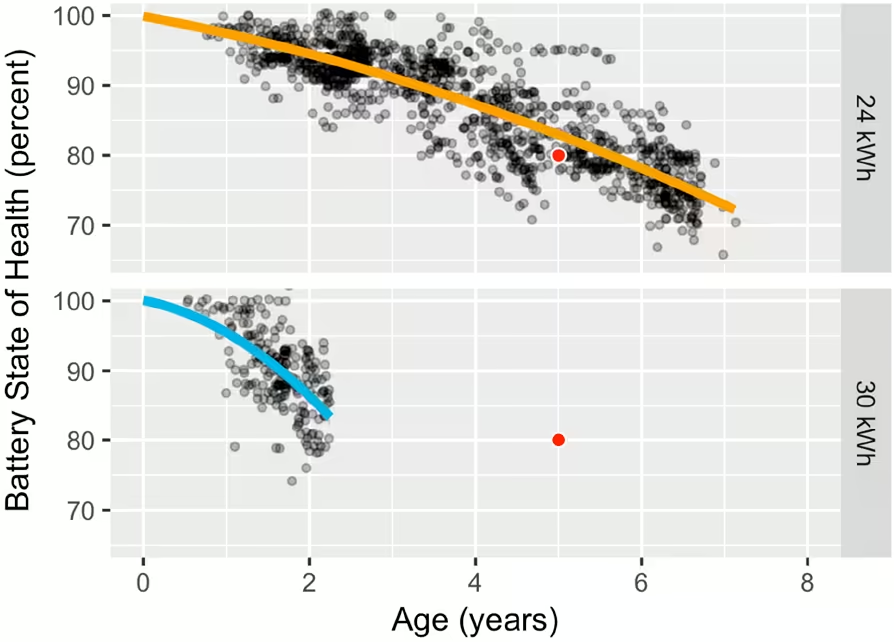

While cyclability performance seems to be much better now and good enough for mass-production, I do expect the cycle life of LMFP battery cells to remain inferior to LFP.

Anyway, the increased cell voltage has its pros and cons. With LMFP you’ll likely get worse cycle life, but higher energy density and pack simplicity.

To have a standard 400-volt (or 800-volt) LMFP battery pack, you need less cells (or groups of cells) connected in series when compared to LFP.

For example, the BYD Dolphin’s battery currently follows a 126s1p configuration (126 cells connected in series), but with LMFP it could be reduced to a simpler 100s1p configuration and still have the same total nominal voltage and capacity. This simplicity advantage of requiring less cells will be further noticed with 800-volt batteries…

Summing up.

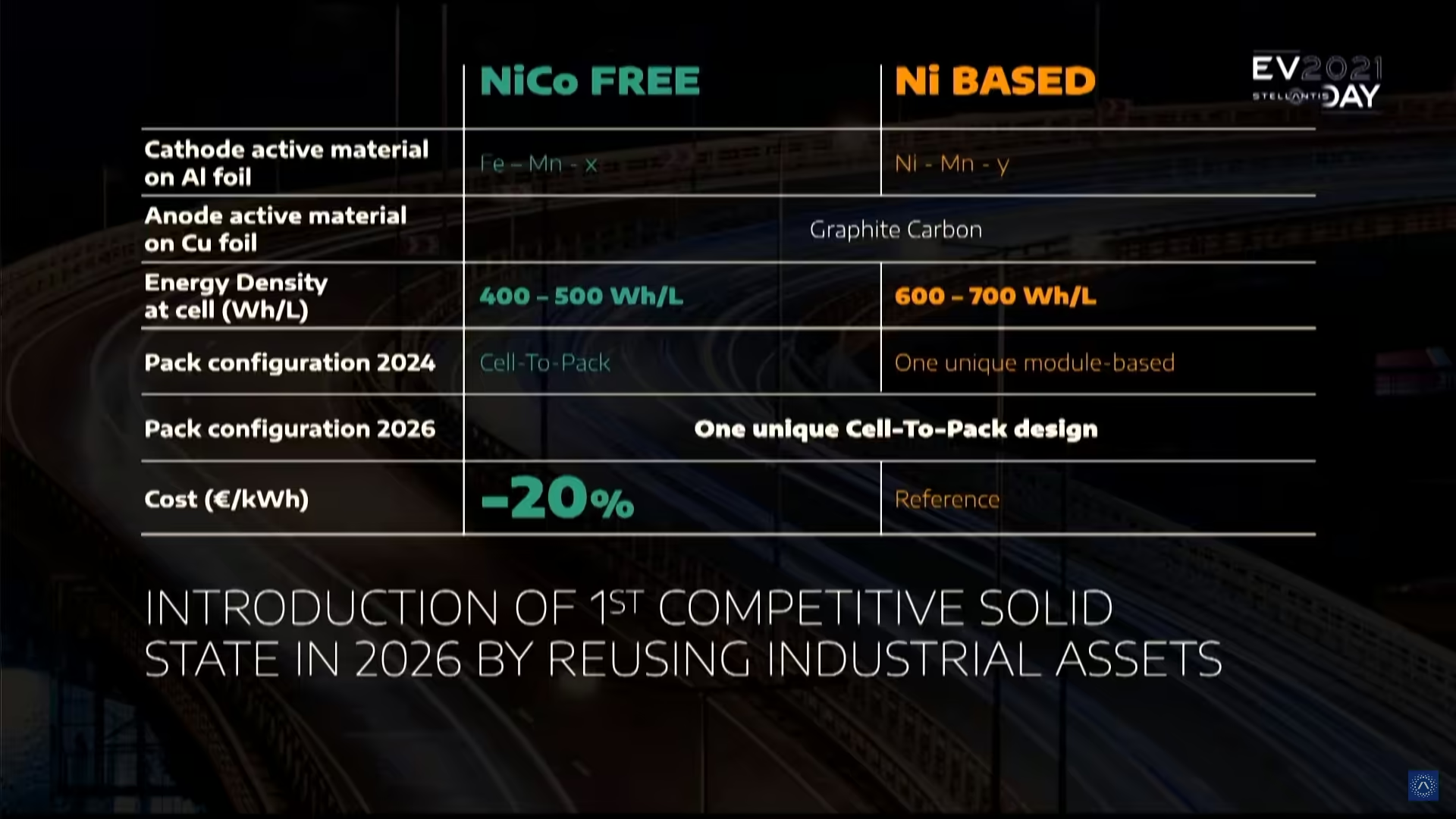

2024 will have great module-less battery packs to power the electric revolution.

- NCM CTP battery: 255 Wh/kg - 70-80 euros per kWh

- LMFP CTP battery: 190 Wh/kg - 50-55 euros per kWh

- LFP CTP battery: 150 Wh/kg - 40-50 euros per kWh

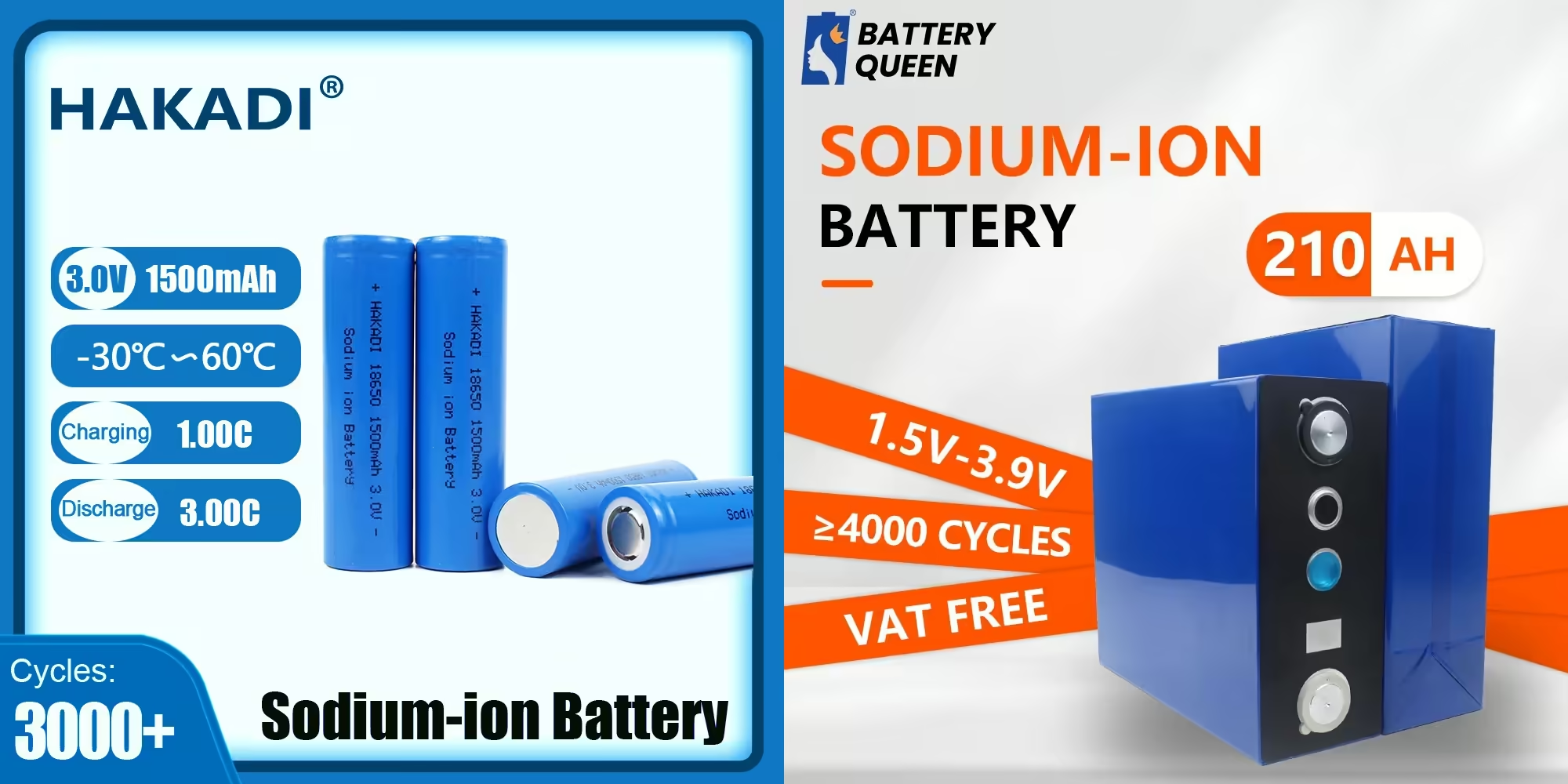

- Sodium-ion CTP battery: 140 Wh/kg - 35-40 euros per kWh (coming soon)

Not having to rely on a sole battery chemistry will help to drive battery costs further down for carmakers.

Now policy makers need to start making polluting cars even harder to sell with higher taxes. Unfortunately, legacy carmakers will only fully embrace electric cars when selling air-poisoning vehicles gets extremely difficult.

More info:

https://carnewschina.com/2024/04/08/byds-2nd-generation-blade-battery-to-launch-this-year/

https://cnevpost.com/2024/01/17/battery-price-war-catl-byd-costs-down/

https://www.mitsui.com/mgssi/en/report/detail/__icsFiles/afieldfile/2023/09/19/2308t_zhao_e.pdf