By the end of 2022, CATL will finally start producing battery cells in Europe (Germany). Machinery is already being installed.

Contemporary Amperex Technology Thuringia GmbH (CATT) is CATL’s first battery plant outside China and will have an initial annual production capacity of 8 GWh, but an increase to 14 GWh is already planned.

Notice that 8 GWh is enough for 160.000 EV battery packs of 50 kWh each, while 14 GWh is enough for 280.000. Not much, but it’s a start…

CATT consists of two buildings: G1, an existing building purchased from another company and where cells are assembled to modules, and G2, a newly-built plant by CATT and where cells will be produced. The approval on Monday was issued to permit cell production of G2.

Stellantis and Tesla are probably the first automakers to get those battery cells. Hopefully, CATL will soon convince them to adopt its CTP (cell-to-pack) technology and go with the simple module-less approach.

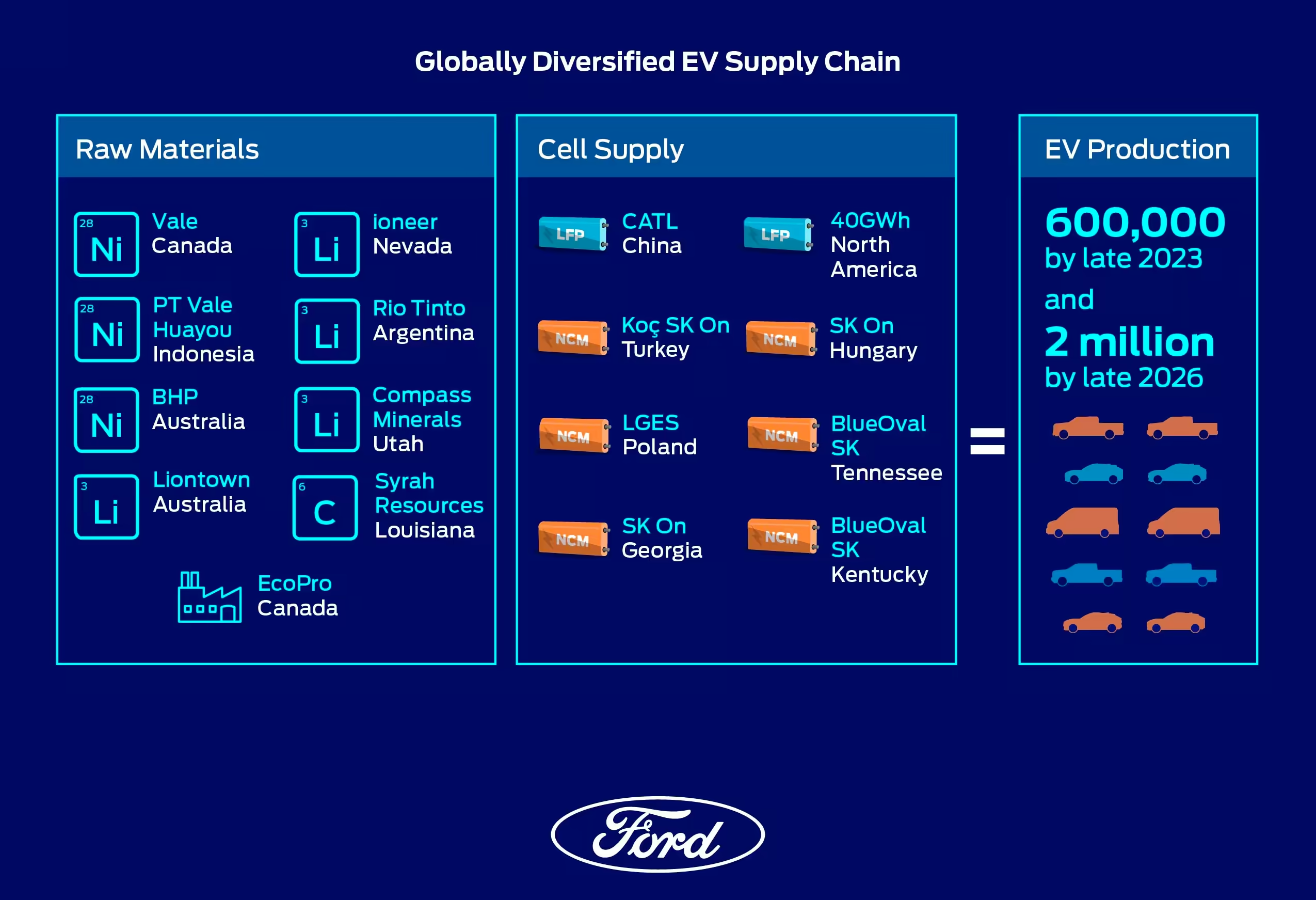

Right now Stellantis gets NCM battery cells from CATL, while Tesla gets LFP.

Anyway, I’m curious to known how the initial battery production capacity will be divided between NCM and LFP (LiFePO4) chemistries. Hopefully, the LFP chemistry will get most of it, since it’s cobalt-free.

Finally, CATL expects to start mass-producing sodium-ion batteries in 2023, maybe the European plant will produce some?! It would be great news for better and cheaper ESS (Energy Storage Systems) that are crucial to accelerate the electrical grid modernization.

More info: