Finally, SVOLT confirmed that it has reached this milestone and their battery cells are available for automakers to order.

Until sodium-ion batteries (NIBs) for electric vehicles become mass-produced in large scale, LFP (LiFePO4) is still the best cobalt-free battery chemistry widely available that allows electric cars to compete with their ICE (Internal Combustion Engine) alternatives, in price and availability.

Nowadays, any development in LFP battery technology is regarded as crucial to enable the massification of electric cars, therefore reaching an energy density of 200 Wh/kg has been a goal for a long, long time.

Moreover, with the CTP (cell-to-pack) technology, where battery packs don’t have modules, a GCTP (gravimetric-cell-to-pack) ratio of 90 % is standard. This means that 200 Wh/kg at the cell level becomes 180 Wh/kg at the pack level. Pretty impressive…

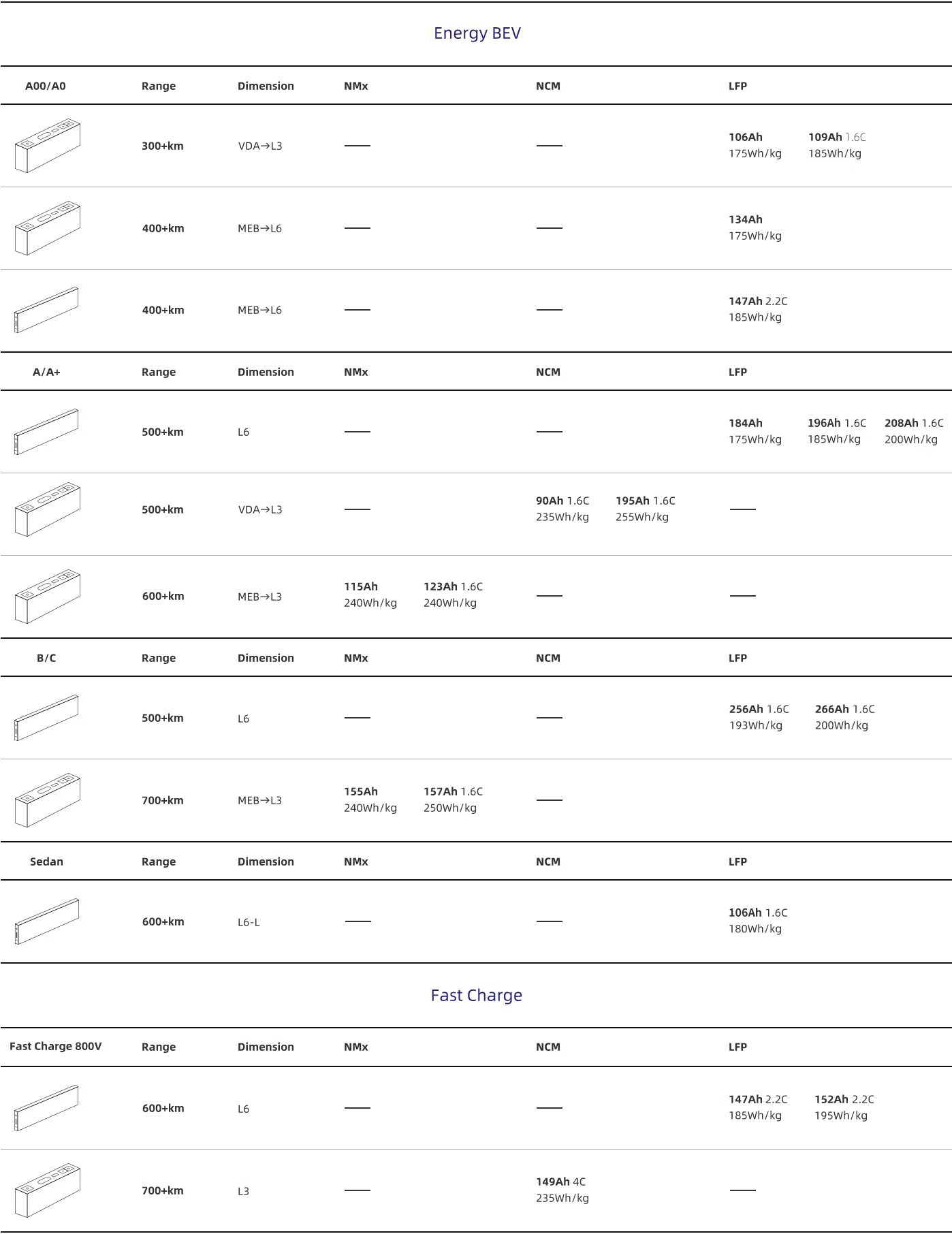

Below we can see the whole range of EV battery cells made by SVOLT that are now available to order.

While NCM will still be used in some cases where energy-density is crucial - like luxury electric sport cars -, the cobalt-free battery technologies NMx (LNMO) and LFP (LiFePO4) are expected to power most mainstream electric cars.

Don’t forget that SVOLT expects to reach 230 Wh/kg with its LFP battery cells by 2023, this represents around 207 Wh/kg at the battery pack level.

Anyway, it’s disappointing that Guoxuan isn’t producing its long-awaited energy-dense LFP battery cells yet, it wouldn’t surprise me if its major shareholder, Volkswagen, is holding this battery technology down. My question is for how long?

More info: