Chinese media is now reporting that Tesla will start using BYD Blade batteries already in the second quarter of next year. This news come shortly after the rumor that Tesla already has a working prototype for its compact hatchback “Model 2” to be made in China.

Could this mean that the upcoming hatchback from Tesla will arrive next year with BYD Blade batteries?

Currently, the Tesla Model 3 SR+ MIC (Made in China) gets its LFP (LiFePO4) battery cells from CATL and at the battery pack level the energy density is only 125 Wh/kg.

However, also with the cobalt-free LFP chemistry the BYD Blade battery packs have an energy density of 140 Wh/kg and 166 Wh/kg at the cell level.

BYD Blade battery cell specs

- Capacity: 202 Ah

- Nominal voltage: 3,2 V

- Max charging voltage: 3,65 V

- Energy: 646,4 Wh

- Length: 905 mm

- Height: 118 mm

- Width: 13,5 mm

- Volume: 1,4 L

- Volumetric energy density: 448 Wh/L

- Weight: 3,9 kg (estimation)

- Gravimetric energy density: 166 Wh/kg

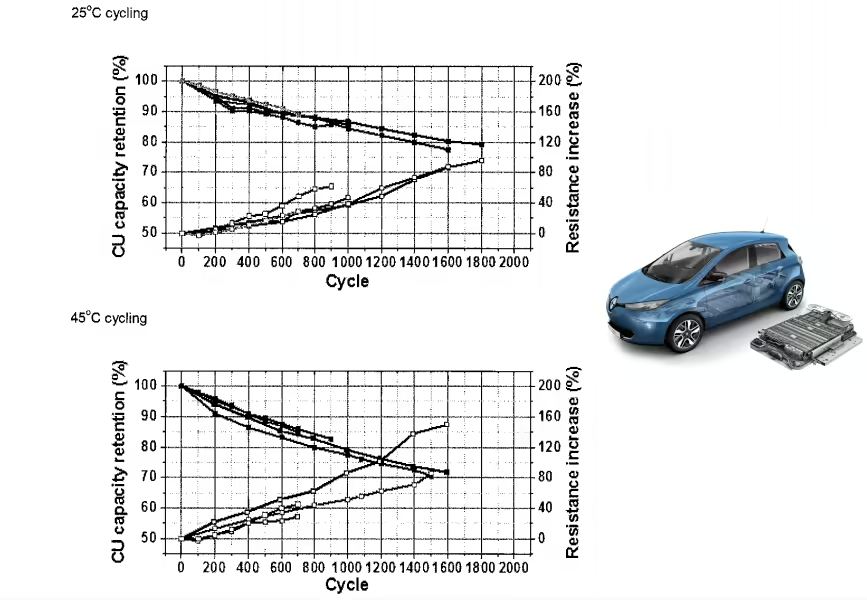

- Cycle life: above 3.000 cycles

- Chemistry: LiFePO4 (LFP)

You probably already know my opinion about the BYD Blade battery. I think that it’s the best battery pack available today, thanks to its low cost, high safety, durability, simplicity and good performance.

If Tesla adopts this battery pack in its upcoming affordable compact hatchback it’ll definitely get a thumbs up from me.

What do you think? Is the BYD Blade battery the right one for Tesla’s most affordable model?

More info:

https://cnevpost.com/2021/08/05/byd-said-to-supply-blade-battery-to-tesla-next-year/