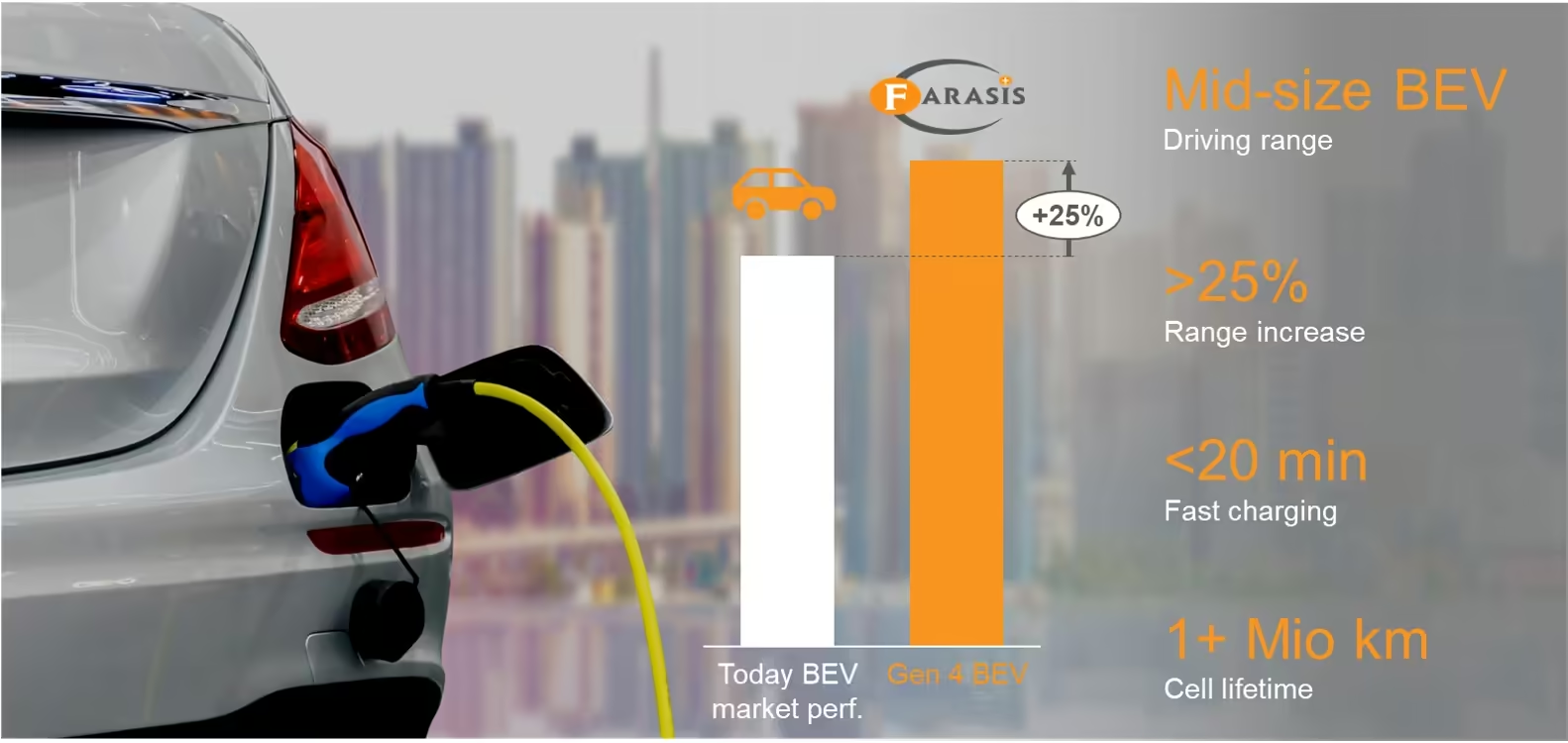

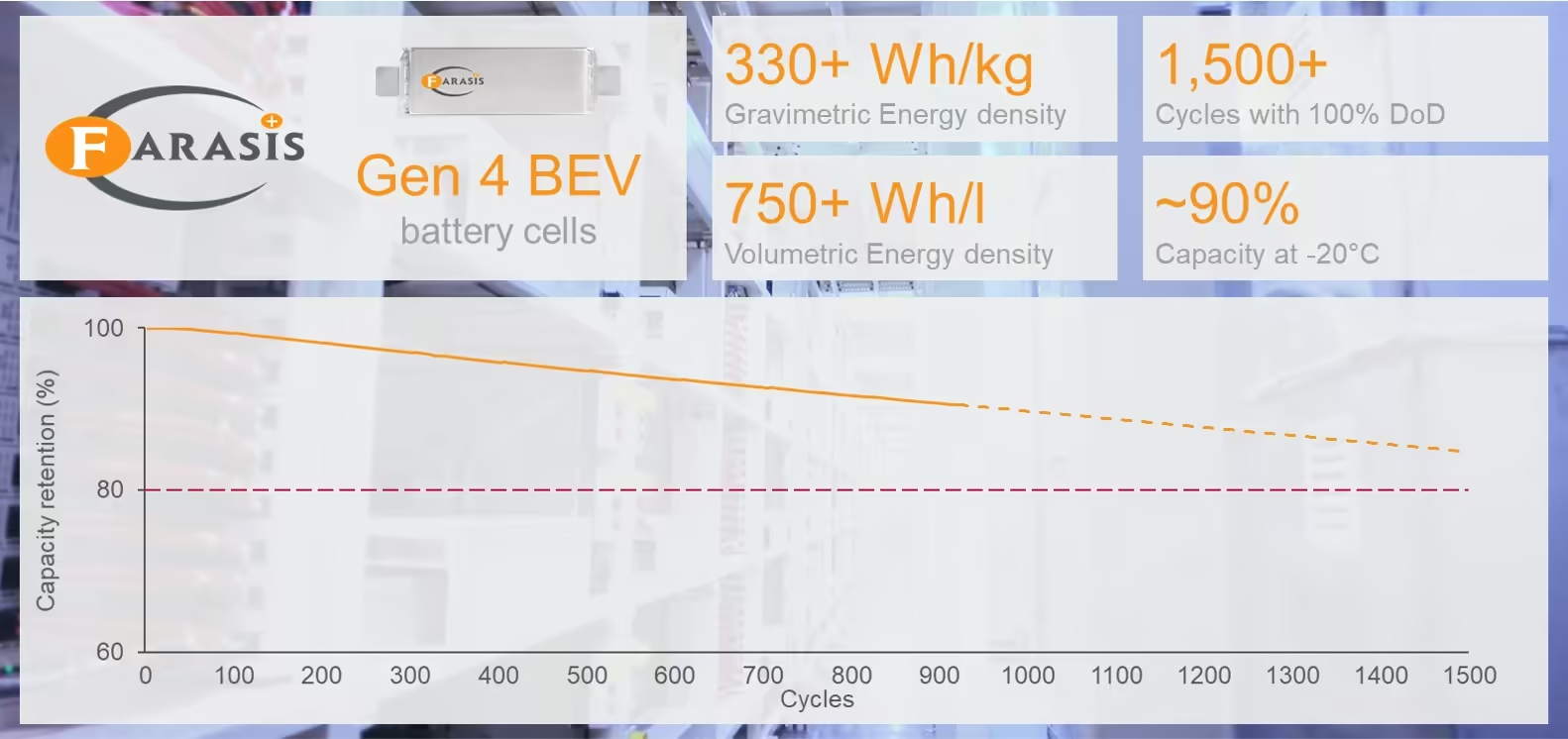

The Chinese battery cell maker Farasis Energy announced the fourth generation of its battery cells.

Thanks to silicon anodes, the new battery cells are extremely energy dense and reach impressive gravimetric and volumetric energy densities (330 Wh/kg and 750 Wh/L).

Let’s see the press release and then the highlights of this new generation of battery cells.

Under the technology research and development ideas of the first generation, the reserve generation, and the development generation, Funeng Technology’s R&D team has made a breakthrough in the energy density of the battery. The energy density of the power battery reaches 330Wh/kg, and its battery technology limits the silicon material. The huge expansion of charging and discharging, combined with single-walled carbon nanotube conductive agent and new binders and other auxiliary materials, build a stable electrode system.

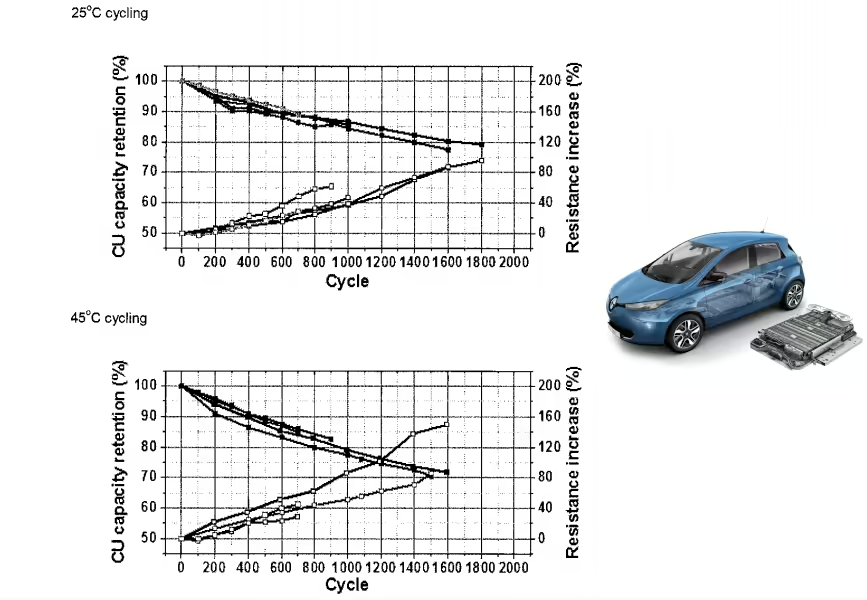

Compared with the existing graphite anode, the 330Wh/kg high energy density battery can greatly reduce the area density of the anode, improve the energy density and charging safety performance of the product, and achieve both the energy density and cycle performance of the battery. At the same time, the high dynamic performance of the battery is realized through the cooperation of the chemical system, so that the battery can still provide about 90% of the capacity at a temperature of minus 20°C. The power battery technology has the advantages of high energy density, long life and high dynamic performance, and fills the current gap in the industry. At the same time, the high-temperature performance of the battery is also excellent, high-temperature storage and high-temperature cycle performance can be higher than the industry level.

Up to now, the technology has passed internal testing. In the future, it will apply to pass the new national standard GB38031-2020 test of the China Automotive Engineering Research Institute Co., Ltd. Testing Center according to market demand. The expected test cycle is about 3 months. After the test, it can be sold and used.

The advent of a new generation of power batteries will effectively solve the user’s mileage anxiety, fully meet market demand, and will also bring new impetus to the new energy power battery industry.

Translated from Chinese to English by Google Translator

Farasis Energy Gen 4 battery cells highlights

- Gravimetric energy density: 330 Wh/kg

- Volumetric energy density: 750 Wh/L

- Cycle life: 1.500 full charge/discharge cycles (100 % of DoD)

- Capacity at extremely cold temperature (-20 ºC): around 90 %

- Fast charging: 20 minutes

While not mentioned in the press release, this 4th generation should be a high nickel and low cobalt content battery cell, either NCM or NCMA.

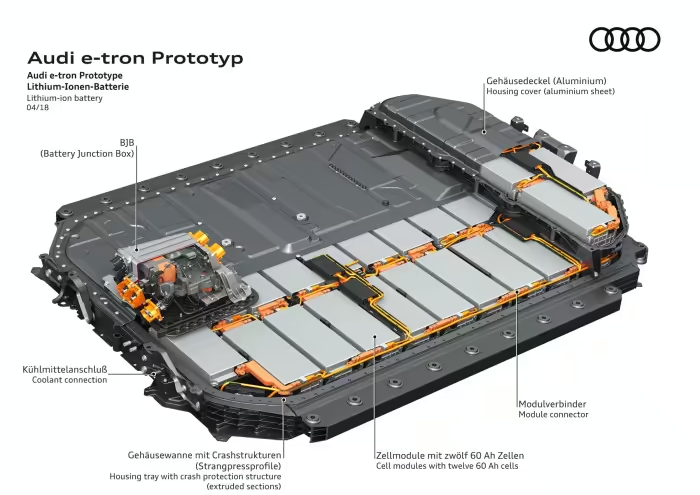

At the battery pack level, we can expect an energy density around 230 Wh/kg, estimated with a GCTPR (gravimetric cell-to-pack ratio) of 70 %.

Currently, the Chinese electric car BAIC EX3 powered by a NCM battery made by Guoxuan holds the record with an energy density of 200 Wh/kg.

Anyway, Farasis says that this generation is almost ready for mass production.

Moreover, Farasis already provides battery cells to the popular electric motorcycles manufacturer, Zero Motorcycles. Therefore, soon we might see the new generation of battery cells not only in electric cars, but also motorcycles…

Finally, it’s worth mentioning that silicon anodes can also be applied to increase the energy density of cobalt-free battery cells, such as the new LFP (LiFePO4) battery cells developed by Guoxuan.

The technology to finally completely replace ICE (Internal Combustion Engine) vehicles already exists. We’ll see how much longer will legacy automakers stay in the ICE age. Probably only as long as politicians allow it.

More info:

http://www.farasis.com/index/news-detail/infoid/334