The Chinese electric car BAIC EX3 was recently upgraded and is now powered by a NCM battery made by Guoxuan with an energy density of 200 Wh/kg. This is the most energy dense battery pack to power a mass produced electric car.

Guoxuan is already known to produce the most energy dense cobalt-free LFP (LiFePO4) batteries, now this Chinese battery cell maker - partly owned by Volkswagen - proves that it can also make extremely energy dense NCM batteries.

Since its launch, this electric car - that resembles a Chevrolet Bolt EV - already had three editions, 2019, 2020 and now 2021. While the price of the new 2021 edition isn’t known yet, the previous 2020 edition had a starting price of 119.900 yuan (15.439 euros).

Let’s see some details of the BAIC EX3.

BAIC EX3 (BJ7000USD8-BEV)

- Length: 4.200 mm

- Width: 1.780 mm

- Height: 1.638 mm

- Gross weight: 1.940 kg

- Curb weight: 1.540 kg

- Maximum speed: 150 km/h

- Range: 470 km (NEDC)

- Energy density of battery: 200,22 Wh/kg

- Consumption: 13,6 kWh/100 km (NEDC)

- Battery type: ternary lithium ion battery (NCM)

- Motor type: permanent magnet synchronous motor

- Motor peak power: 120 kW and 240 N.m of torque

Battery details

- Capacity: 63,3 kWh

- Weight: 315 kg

- Energy density: 200,22 Wh/kg

- Maker: Guoxuan

- Type: NCM

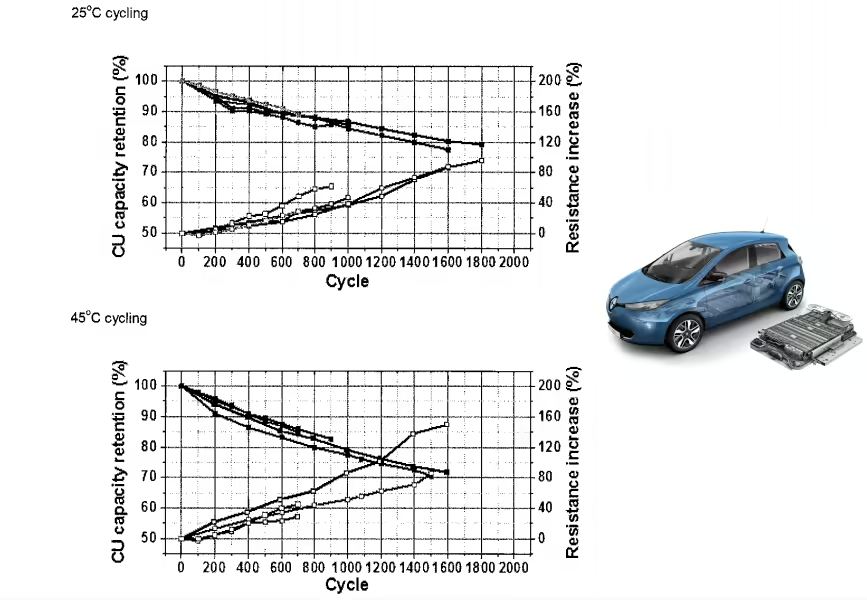

For comparison, the NCM 712 battery made by LG Chem that powers the new Renault ZOE has a total capacity of 55 kWh and weighs 326 kg.

A lighter battery not only contributes to make electric cars more efficient, but also contributes to make them cheaper, since fewer raw materials were used in production.

Anyway, how does this NCM battery pack compares to the LFP technology produced by Guoxuan?

Guoxuan’s LFP battery cell evolution

- 2009: 95 Wh/kg

- 2015: 140 Wh/kg

- 2019: 190 Wh/kg

- 2020: 212 Wh/kg (191 Wh/kg at pack level with JTM)

- 2021: 230 Wh/kg (207 Wh/kg at pack level with JTM)

- 2022: 260 Wh/kg (234 Wh/kg at pack level with JTM)

As you can see, Guoxuan also expects to surpass the 200 Wh/kg mark at the pack level with its cobalt-free LFP battery cells already this year, by using extremely compact and simple cell modules (JTM technology).

In China the number of new electric vehicles introduced with LFP batteries is rising extremely fast.

MIIT approved 202 #NEV models for sales in Feb.

— Moneyball (@DKurac) March 15, 2021

PV: 50#LFP: 44%#NMC: 54%#LMO: 1%#FCEV: 1%#CATL led OEM with 12 models, #Guoxuan followed with 3.

(GGII) pic.twitter.com/M9X8NlyAQa

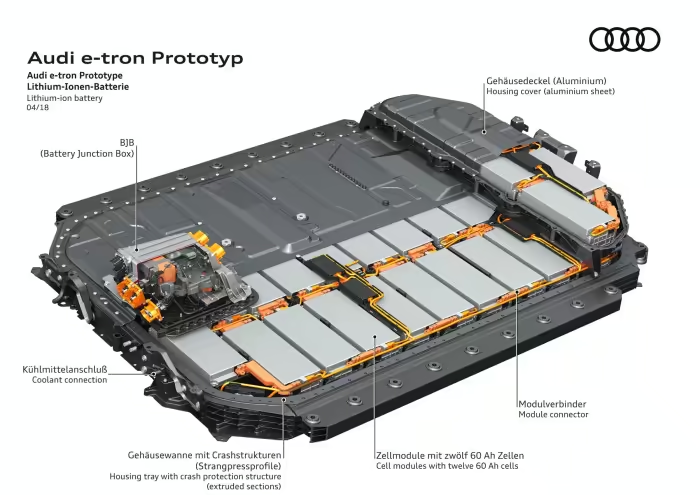

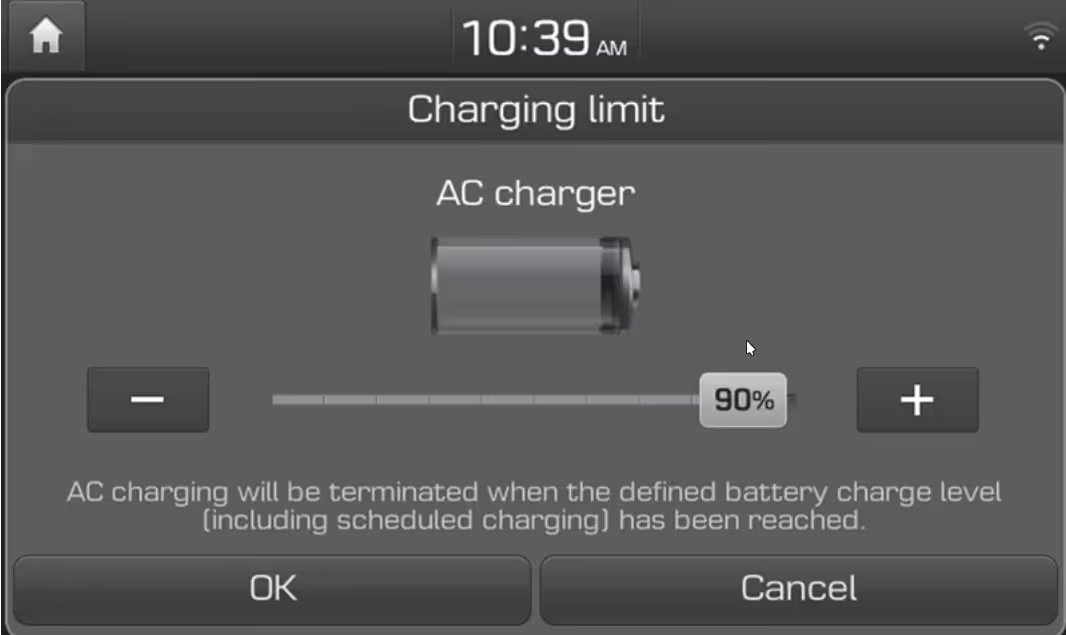

While NCM battery cells are more energy dense, at the battery pack level they lose this advantage by requiring more hardware to protect them, since they are inherently less safe than LFP cells. The extra protection hardware not only adds more weight, it also increases costs.

More info: