Guoxuan is a Chinese battery cell maker known for producing the most energy-dense cobalt-free LFP (LiFePO4) battery cells.

Late last year this manufacturer reached a record-breaking energy density of 212 Wh/kg for a LFP battery cell, made with a LFP cathode and a silicon anode. Now, Guoxuan is providing more details about this pouch battery cell.

Battery cell specs

- Capacity: 55 Ah

- Voltage: 3,2 V

- Energy: 176 Wh

- Weight: 830 g

- Energy density: 212 Wh/kg

Moreover, Guoxuan has the goal of reaching 230 Wh/kg already during this year and 260 Wh/kg in 2022.

Guoxuan’s LFP battery cell evolution

- 2009: 95 Wh/kg

- 2015: 140 Wh/kg

- 2019: 190 Wh/kg

- 2020: 212 Wh/kg (191 Wh/kg at pack level with JTM)

- 2021: 230 Wh/kg (207 Wh/kg at pack level with JTM)

- 2022: 260 Wh/kg (234 Wh/kg at pack level with JTM)

#Guoxuan presents its 212 Wh/kg #LFP pouch cell that uses silicon based anode/pre-lithation tech, #China media citing company.

— Moneyball (@DKurac) January 9, 2021

Capacity: 55 Ah

Weight: 830 g

Cathode gram capacity: 150 mAh/g

Cathode compaction density: 2.4 g/cc

2021 Guoxuan target is 230 Wh/kg. pic.twitter.com/aAc4ElDAgC

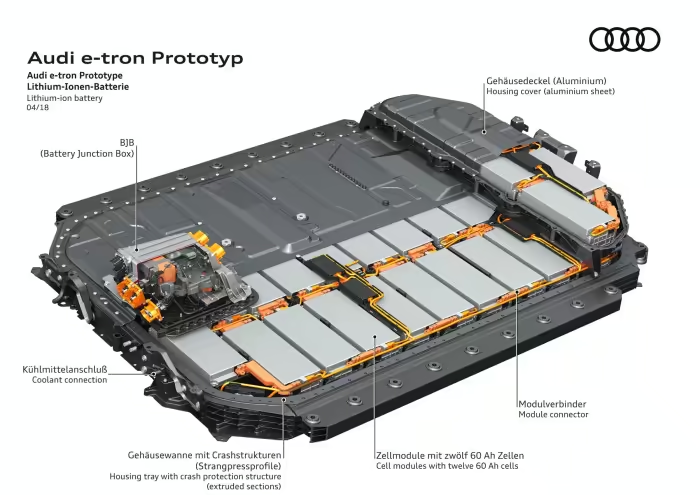

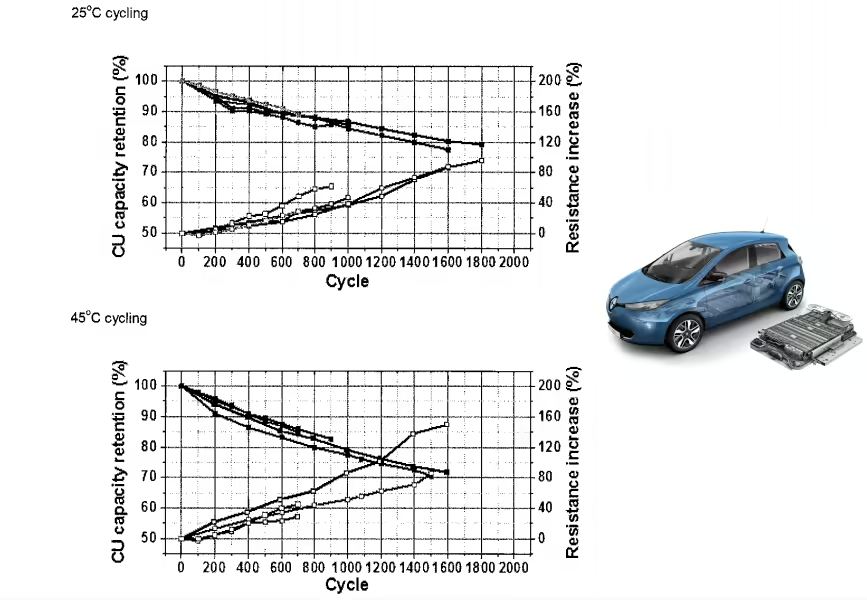

Being an inherently safe battery chemistry, battery packs made with LFP (LiFePO4) cells don’t require much safety equipment, such as metal firewalls between cells or a complex TMS (Thermal Management System). This means that the GCTPR (gravimetric cell-to-pack ratio) for this battery chemistry is higher than what we have with NCM or NCA battery packs.

Guoxuan uses the JTM (Jelly roll-to-module) technology to achieve a record-breaking GCTPR of 90 %.

Let’s see what kind of battery packs can we have with the battery cell recently unveiled by Guoxuan.

Hypothetical battery pack 1

- Configuration: 136s1p

- Energy: 23,9 kWh

- Weight (cells): 113 kg

- Weight (pack): 125 kg (estimated from a GCTPR of 90 %)

- Cost: 1.915 euros (estimated with 80 euros per kWh)

Hypothetical battery pack 2

- Configuration: 136s2p

- Energy: 47,9 kWh

- Weight (cells): 226 kg

- Weight (pack): 251 kg (estimated from a GCTPR of 90 %)

- Cost: 3.830 euros (estimated with 80 euros per kWh)

Hypothetical battery pack 3

- Configuration: 136s3p

- Energy: 71,8 kWh

- Weight (cells): 339 kg

- Weight (pack): 376 kg (estimated from a GCTPR of 90 %)

- Cost: 5.745 euros (estimated with 80 euros per kWh)

Considering that Volkswagen is the biggest stakeholder of Guoxuan, we might see the German automaker adopting this technology soon.

More info: