NFA may soon join LNMO and LFMP as a promising cobalt-free cathode chemistry for EV batteries.

Highlights

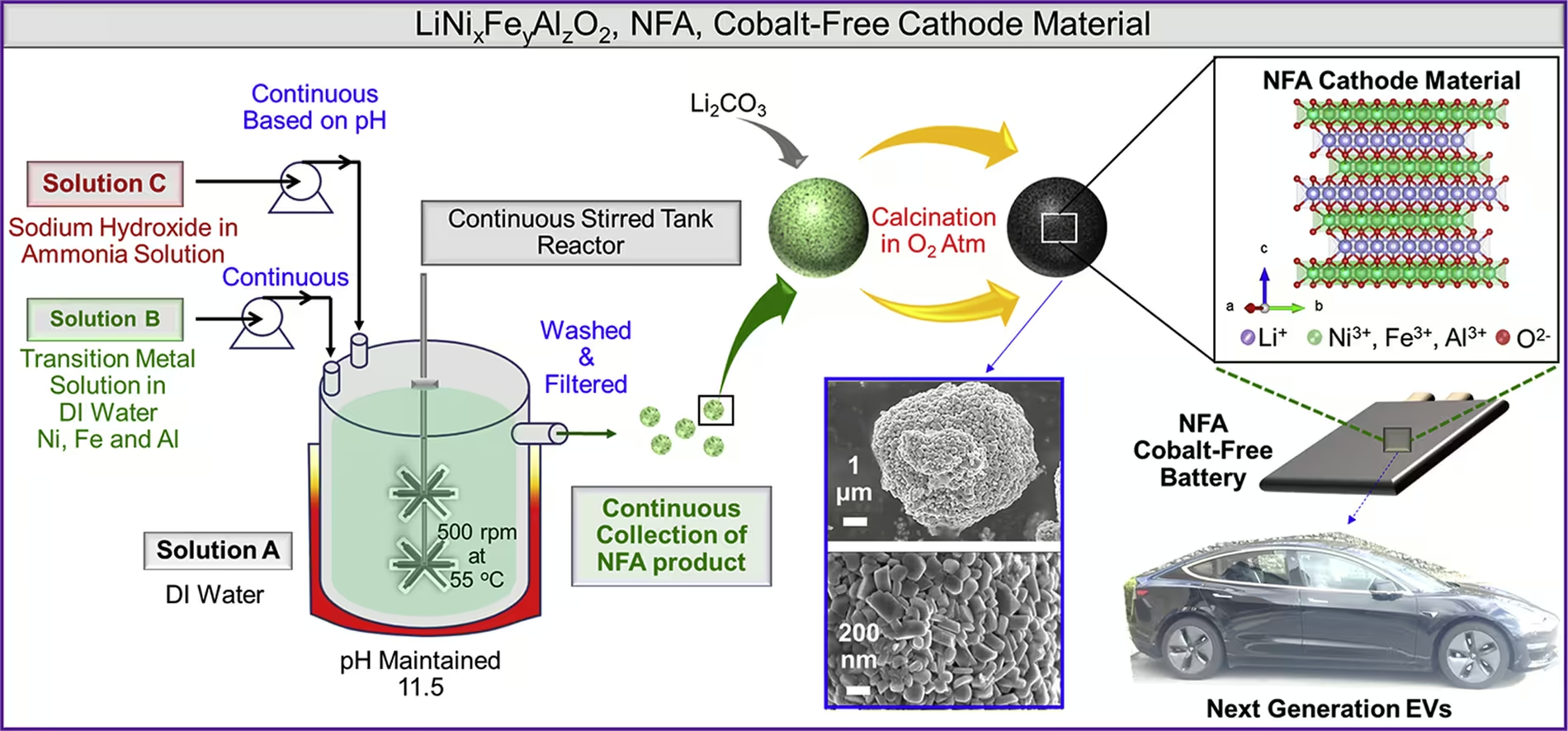

- Introducing a new class of cobalt-free, nickel-rich layered cathode (LiNixFeyAlzO2).

- Our cobalt-free cathode powders were synthesized using co-precipitation process.

- Our cobalt-free cathodes delivered high capacities ~190 mAh/g at 0.1C.

- We also fabricated a 0.5 Ah (C/3) cobalt-free Li-ion battery pouch cell.

- The cobalt-free battery delivered good capacities and cycling performance.

Oak Ridge National Laboratory researchers have developed a new family of cathodes with the potential to replace the costly cobalt-based cathodes typically found in today’s lithium-ion batteries that power electric vehicles and consumer electronics.

The new class called NFA, which stands for nickel-, iron- and aluminum-based cathode, is a derivative of lithium nickelate and can be used to make the positive electrode of a lithium-ion battery. These novel cathodes are designed to be fast charging, energy dense, cost effective, and longer lasting.

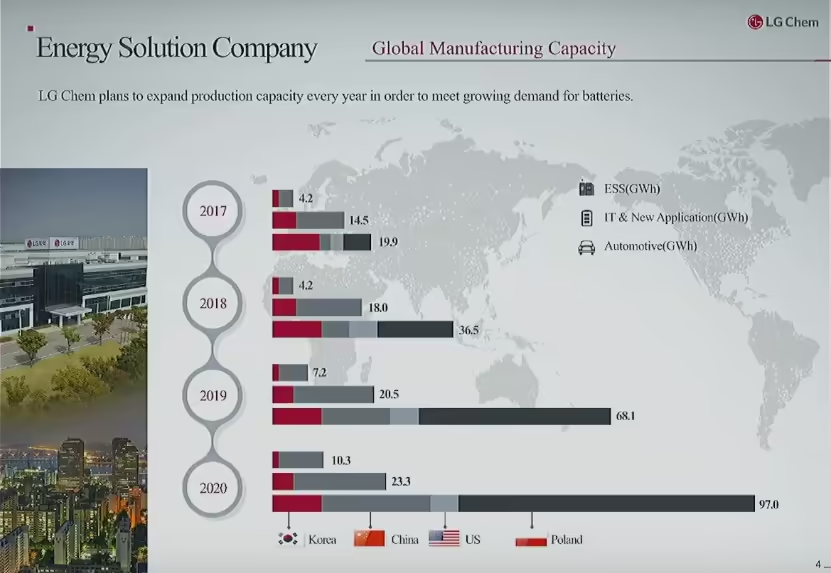

With the rise in the production of portable electronics and electric vehicles throughout the world, lithium-ion batteries are in high demand. According to Ilias Belharouak, ORNL’s scientist leading the NFA research and development, more than 100 million electric vehicles are anticipated to be on the road by 2030. Cobalt is a metal currently needed for the cathode which makes up the significant portion of a lithium-ion battery’s cost.

Although research on the NFA class is in the early stages, Belharouak said that his team’s preliminary results to date indicate that cobalt may not be needed for next-generation lithium-ion batteries.

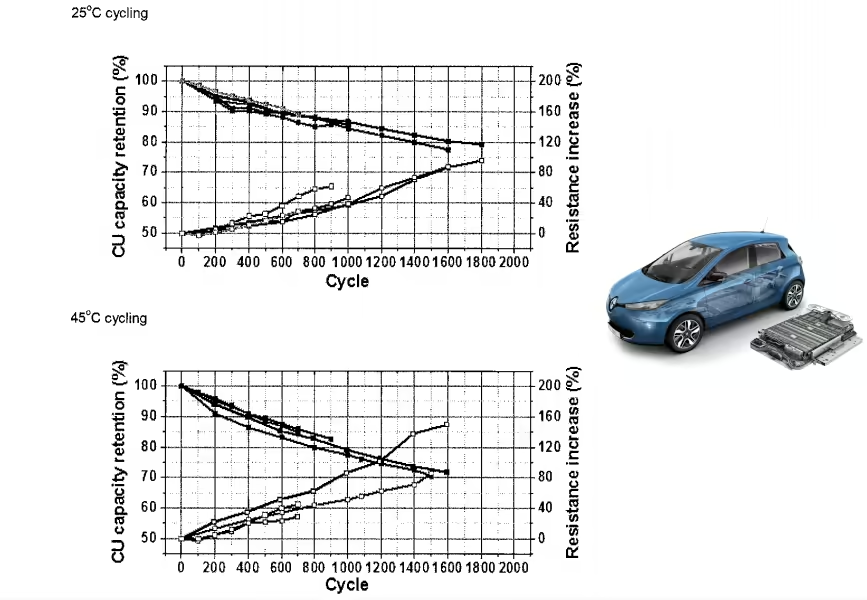

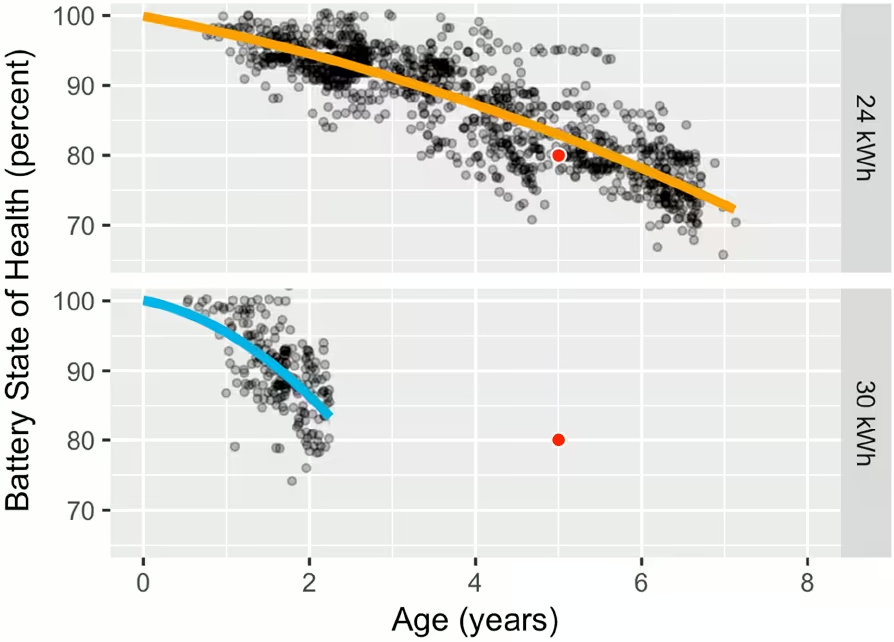

NFA (nickel, iron and aluminum-based cathode) is still in an early stage of development. Right now the energy density is good but the cycle life is still very poor, with only 88 % capacity retained after 100 cycles and 72 % after 200 cycles.

But don’t worry, in this initial phase of development the poor cycle life is to be expected. Just a few years ago, the first NCM 811 batteries developed in the lab also had a very poor cycle life, but now the mass-produced technology has an EOL (End-Of-Life) that already surpasses 1.000 cycles.

Anyway, it’s yet to be seen if this new cobalt-free cathode chemistry will ever be adopted by a major battery cell maker.

While the Chinese giant CATL is already producing cobalt-free LFP batteries, Korean and Japanese battery cell makers are still undecided on which cobalt-free battery chemistry to adopt. My guess is that it will be LNMO, but we’ll see…

More info:

https://www.sciencedirect.com/science/article/pii/S0378775320306935

https://sci-hub.se/https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.202002960