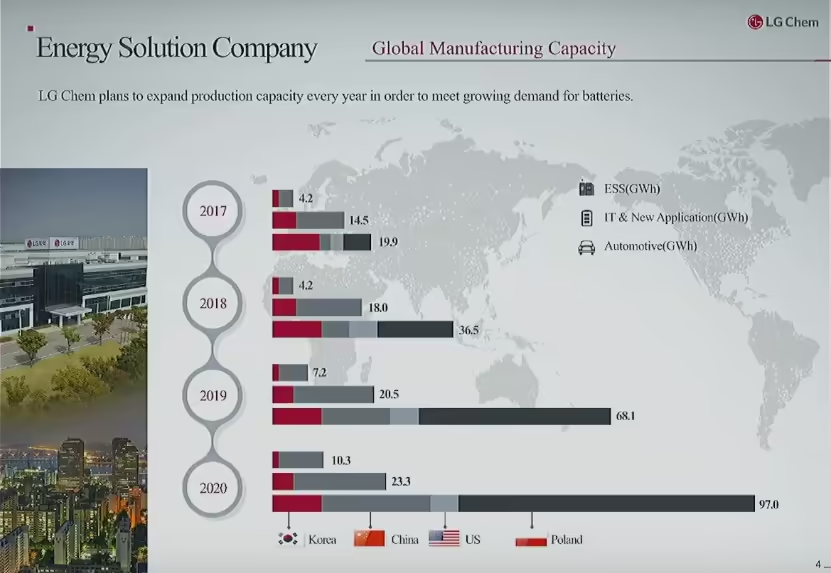

Only behind CATL and BYD, Guoxuan High-Tech Power Energy is China’s third biggest battery cell maker with an annual production capacity expected to reach 28 GWh already this year - enough for more than half-million (560.000) battery packs with 50 kWh each.

Recently the giant German automaker Volkswagen acquired 26 % of Guoxuan’s parent company Gotion that is now preparing for a fast growth. Not only in production capacity, but also in technological advancements.

Regarding production capacity, Guoxuan plans to reach an output of 80 GWh by 2023 and 100 GWh by 2025.

As for energy density goals, according to its vice president Huang Zhangxi, Guoxuan plans to reach 260 Wh/kg with cobalt-free LFP cells and 350 Wh/kg with NCM cells by 2022.

Guoxuan will also strive to improve the energy storage capacity of its batteries, raising the energy density of its lithium iron phosphate batteries to 260 watt-hours per kilogram and that of its MnNiCo ternary batteries to 350 Wh/kg by 2022.

#Guoxuan to expand capacity to 28 GWh this year, 80 GWh by 2023 as it aims at 100 GWh by 2025, #China #battery maker reveals.

— Moneyball (@DKurac) October 26, 2020

The company targets 260 Wh/kg #LFP and 350 Wh/kg #ternary battery by 2022, company added. pic.twitter.com/V6VFfJ5qTI

Anyway, currently Guoxuan’s most energy dense LFP battery cells have an energy density around 190 Wh/kg. During this year, Guoxuan expects to reach 210 Wh/kg, but mass production will probably only begin in 2021.

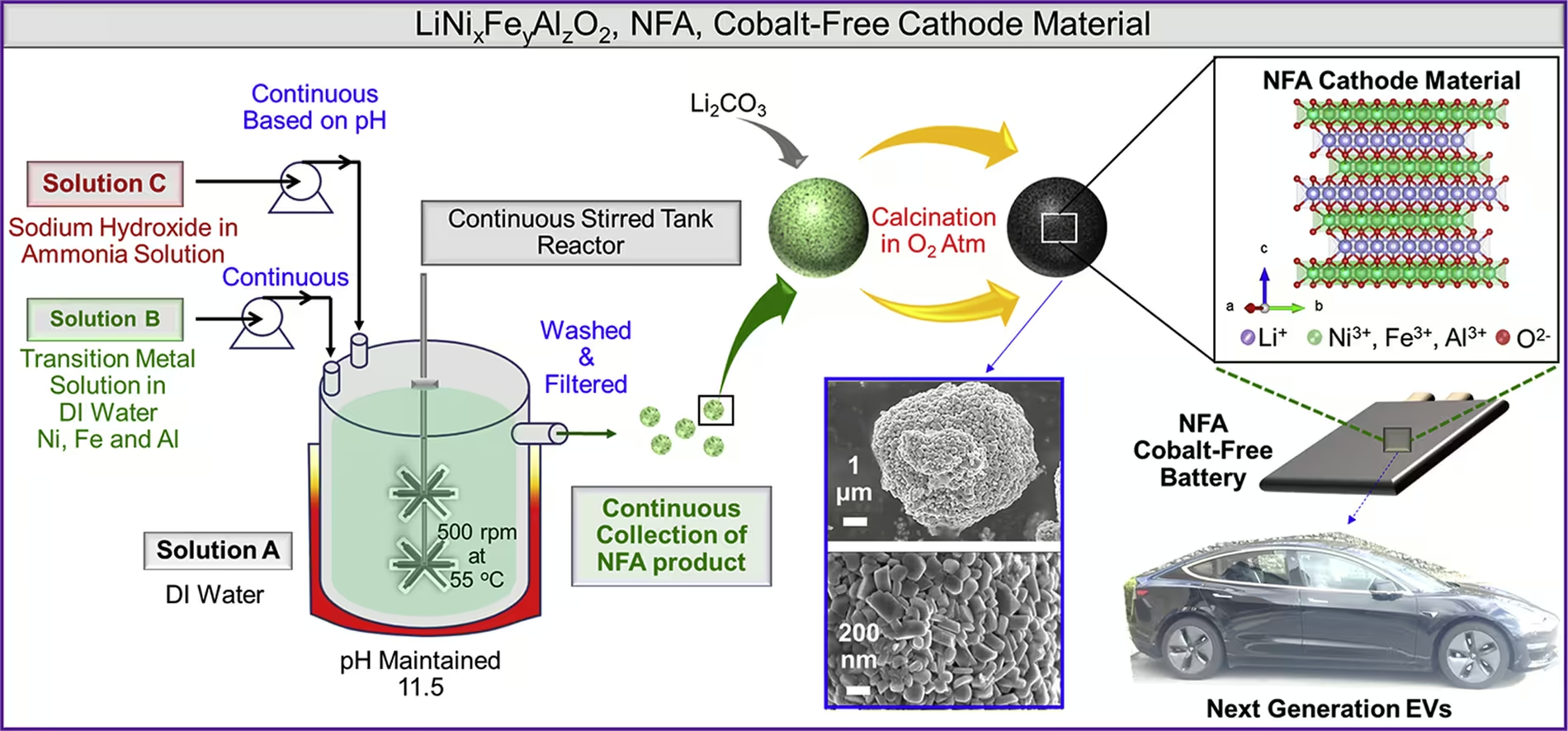

Achieving 260 Wh/kg by 2022 would be extremely impressive for cobalt-free LFP (LiFePO4) battery cells, I suspect that those will be LFMP (high-voltage version of LFP). Considering a GCTPR (gravimetric cell-to-pack ratio) of 85 % that is common in CTP (cell-to-pack) batteries, it would possible to achieve 221 Wh/kg at the battery pack level with those extremely safe, durable and cheap cells.

As for the NCM battery cells that are expected to reach 350 Wh/kg, those are likely to be the NCMA variant, which is the next logical step in NCM/NCA advancements. However, since this kind of cells require a lot more safety equipment when compared to inherently safe LFP/LFMP cells, the GCTPR is always lower. Therefore, we can expect around 250 Wh/kg at the battery pack level with NCMA battery cells.

At the battery pack level, the energy density differences between LFMP and NCMA batteries will be minimal, only justified for more expensive electric cars that require that extra range, no matter the cost. For high-volume production electric cars, cobalt-free LFMP or LNMO batteries will be the better choices.

I’m curious to know if Volkswagen and Guoxuan plan to build cobalt-free batteries in Europe and North America anytime soon.

More info: