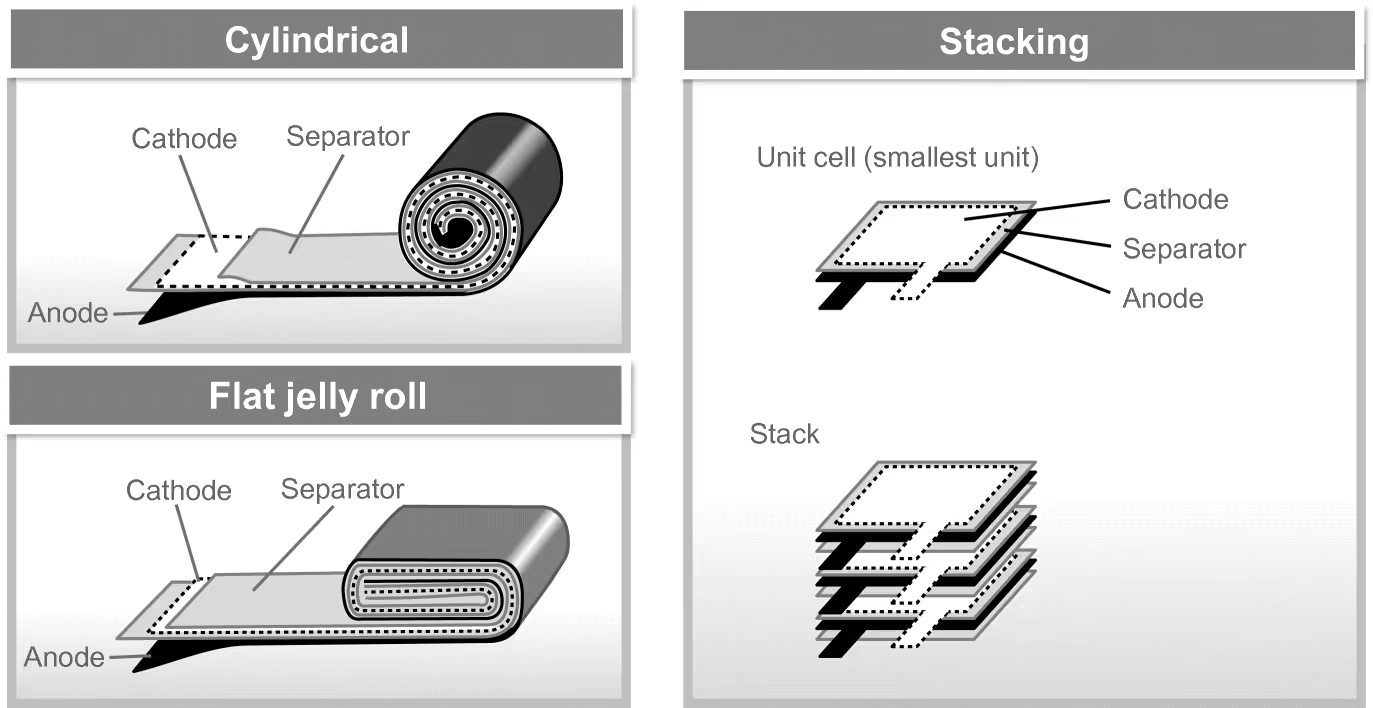

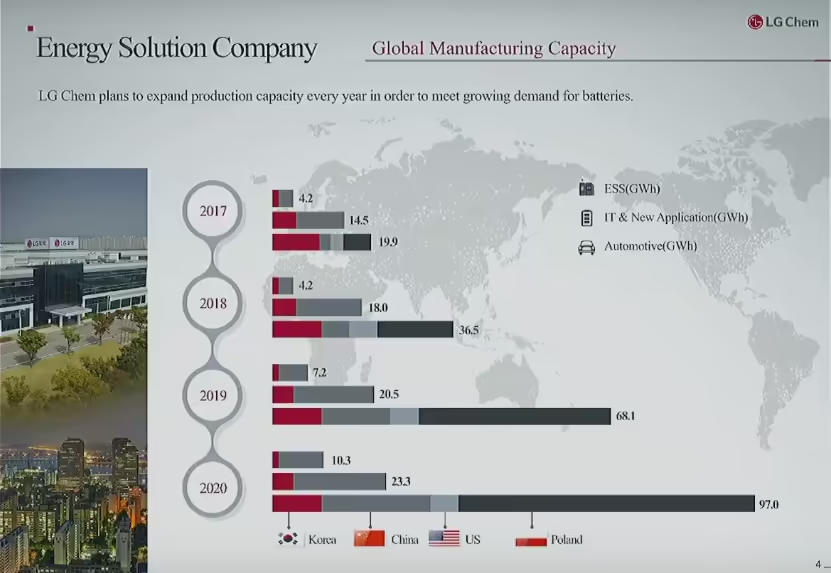

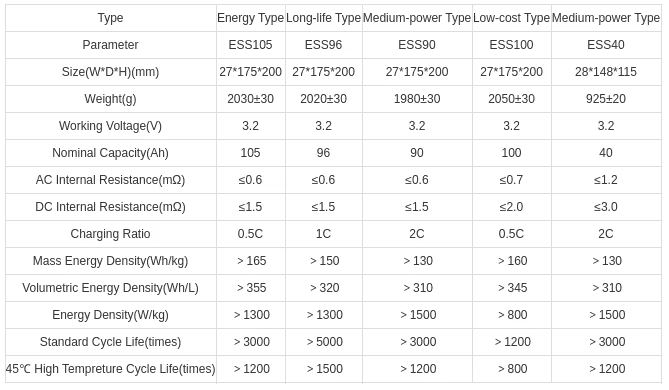

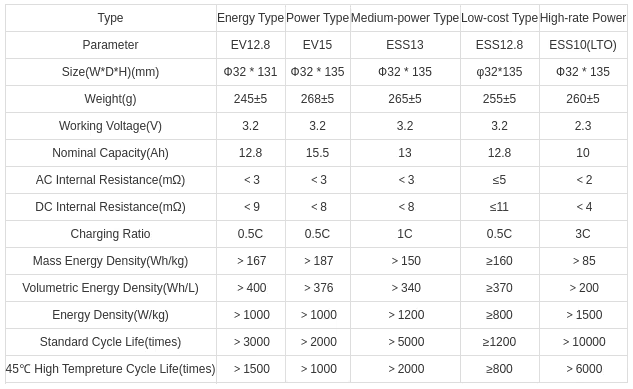

Guoxuan is an important battery cell maker in China specialized in cobalt-free LFP (LiFePO4) battery cells that also makes long-lasting LTO cells. It produces cells in both cylindrical and prismatic forms.

This company currently supplies cobalt-free LFP battery cells to make the extremely affordable electric car Wuling Hong Guang MINI EV.

Guoxuan prismatic battery cells

Guoxuan cylindrical battery cells

Currently its most energy dense commercial LFP battery cells are in the cylindrical form and already surpass 187 Wh/kg, but Guoxuan expects to reach 210 Wh/kg during this year.

Our jelly roll-to-module (JTM) tech gives us >90% grouping efficiency with #LFP module density at close to 200 Wh/kg, pack at 180 Wh/kg, #Guoxuan on its LFP dev.

— Moneyball (@DKurac) September 19, 2020

We can produce 190 Wh/kg LFP cell, while in lab we plan to reach 210 Wh/kg this year, Guoxuan added. pic.twitter.com/ZyvGzHZM3c

Gravimetric energy density

- Cell: 210 Wh/kg

- Module: 200 Wh/kg

- Pack: 180 Wh/kg

The GCTPR (gravimetric cell-to-pack ratio) is 86 percent, which is basically what BYD achieves with its CTP Blade battery pack made with LFP prismatic cells. However, BYD’s cells have lower energy density, resulting in a less energy dense battery pack.

A year ago this kind of energy density (above 200 Wh/kg) was only expected to be achieved in LFP cells with the introduction of the high-voltage version LFMP. In comparison with LFP cells, LFMP cells operate at roughly 17 percent higher voltage that corresponds to an increase of energy density of the same amount.

Reaching 180 Wh/kg at the battery pack level with cobalt-free cells is an extremely important step for the massification of electric cars. Currently the electric cars we have available in Europe and North America with more expensive NCM and NCA batteries at best reach 168 Wh/kg.

With cobalt-free batteries electric cars can finally compete with ICE (Internal Combustion Engine) cars on volume production and price.

Some ICE car models have an annual production above one million units and only with a cobalt-free battery an electric car can eventually reach this level.

By the way, for this year the planned annual production of the affordable Wuling Hong Guang MINI EV is 200.000 units and next year is expected to reach half-million units. It’s not one million yet, but it’s getting there…

Even before the Tesla Battery Day, 2020 is a year already marked with exceptional battery technology breakthroughs. Don’t you agree?

More info:

https://www.shanghai-electric.com/group_en/c/2019-08-12/556943.shtml

https://www.grepow.com/blog/winding-vs-stacking-which-is-better-for-lithium-battery/