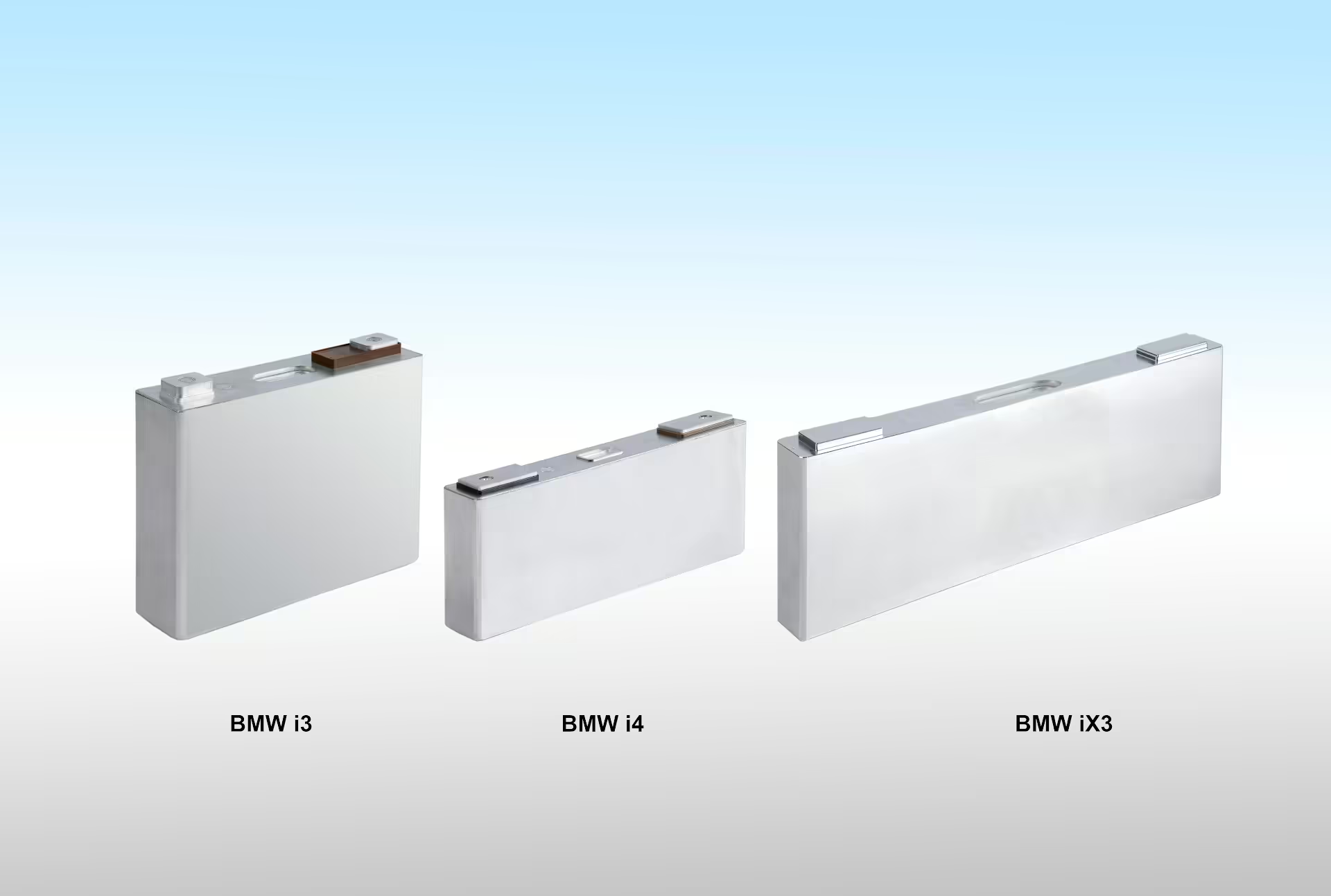

Now that BMW finally unveiled its new electric car, we have more details about its powertrain that includes a NCM 811 battery made with 188 prismatic cells from CATL.

But first, let’s see some important parts of the press release.

- New BMW iX3 will be the brand’s first model to also be produced for export at the Shenyang manufacturing facility in China. Market launch will begin in China later in 2020.

- Strategic “Power of Choice” approach covers broad spread of customer requirements and statutory regulations around the world: BMW X3 is the first model to be available with a petrol or diesel engine, plug-in hybrid drive system or all-electric drive system.

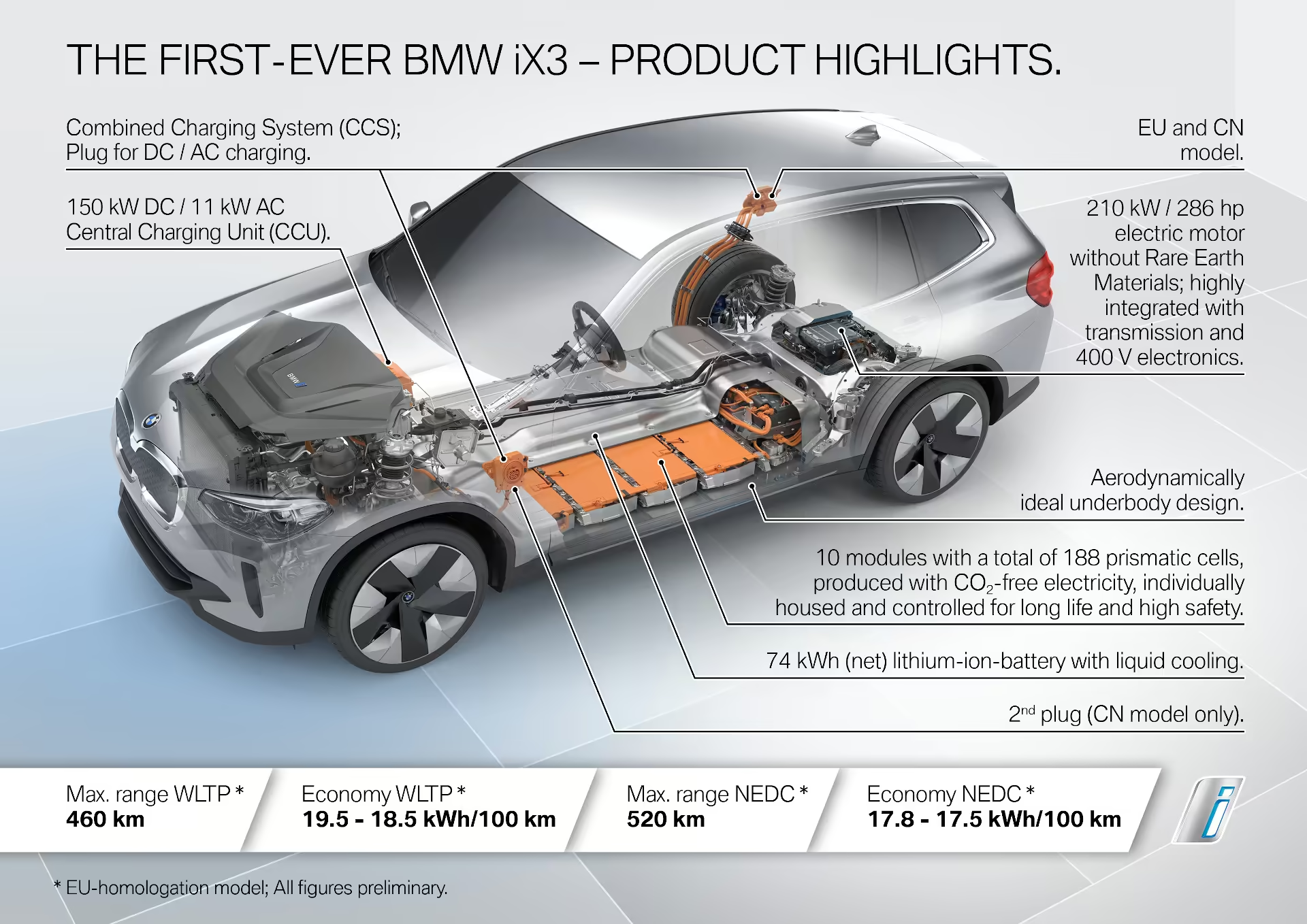

- New BMW iX3 blazes a trail for fifth-generation BMW eDrive technology. Major progress made in terms of power density, operating range, weight, installation space requirement and flexibility. Power density of the electric drive system increased by 30 per cent over the BMW Group’s existing fully electric vehicles; gravimetric energy density of the high-voltage battery at cell level up by 20 per cent. Latest versions of the electric motor, power electronics, charging technology and high-voltage battery (all developed in-house) will also be deployed in the BMW iNEXT and BMW i4 from 2021.

- Efficiency boosted significantly compared with the BMW i3 by highly integrated drive system technology. Electric motor, power electronics and transmission arranged in a central housing for the first time. Fifth-generation BMW eDrive high-voltage battery with the latest battery cell technology and gross energy content of 80 kWh enables operating range of up to 460 kilometres [285 miles] in the statutory new WLTP test cycle (up to 520 kilometres [323 miles] in the NEDC test cycle). BMW Group monitors compliance with environmental and social standards as part of its procurement process for the lithium and cobalt used in battery cells.

- Newly designed fifth-generation BMW eDrive electric motor produces maximum output of 210 kW/286 hp and peak torque of 400 Nm (295 lb-ft). Acceleration from 0 to 100 km/h [62 mph] in 6.8 seconds (for purposes of comparison – BMW X3 30i: 6.4 seconds), top speed (electronically limited): 180 km/h [112 mph]. The design principle of a current-excited synchronous motor enables optimised power development and allows engineers to avoid the use of rare earths.

Specs of the BMW iX3 powertrain

- Motor: 210 kW/286 hp and peak torque of 400 Nm (295 lb-ft)

- Top speed (electronically limited): 180 km/h (112 mph)

- Acceleration: from 0 to 100 km/h (62 mph) in 6,8 seconds

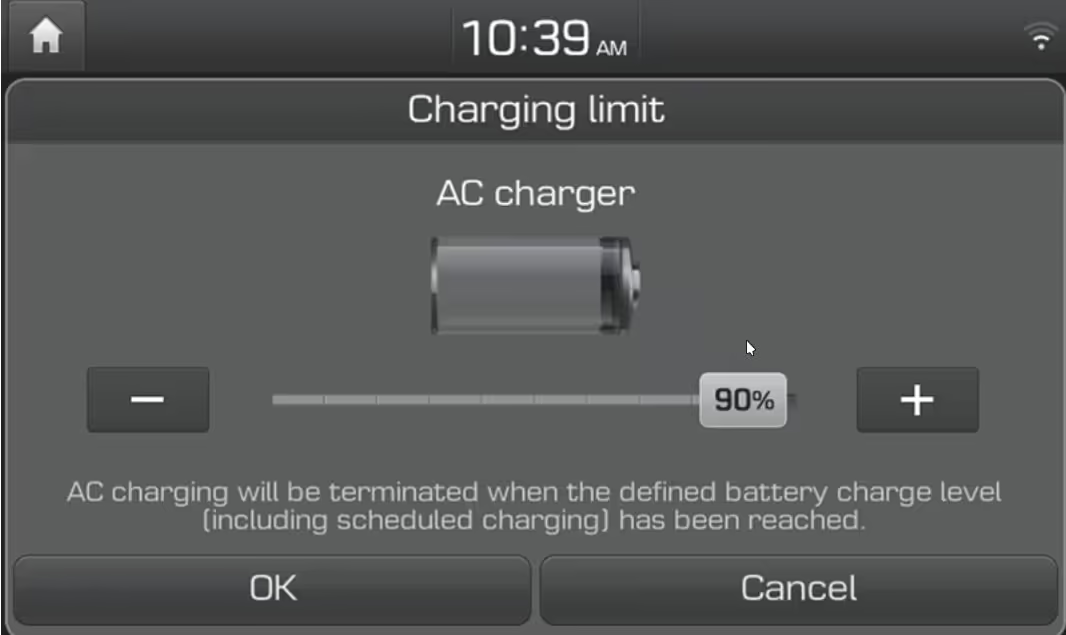

- Fast charging: 0 to 80 % in 34 minutes at 150 kW CCS chargers

- On-board charger: 11 kW and 22 kW (optional)

- WLTP range: 460 km (286 miles)

- NEDC range: 520 km (323 miles)

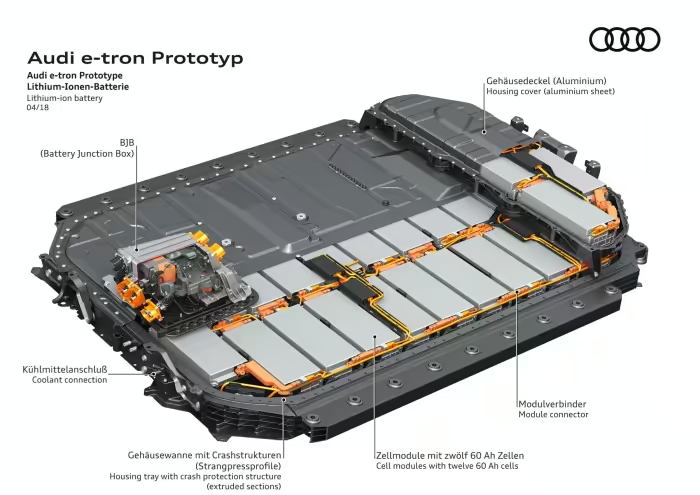

- Total battery capacity: 80 kWh (10 modules)

- Usable battery capacity: 74 kWh (92 %)

- Battery cells: 188 prismatic (94s2p)

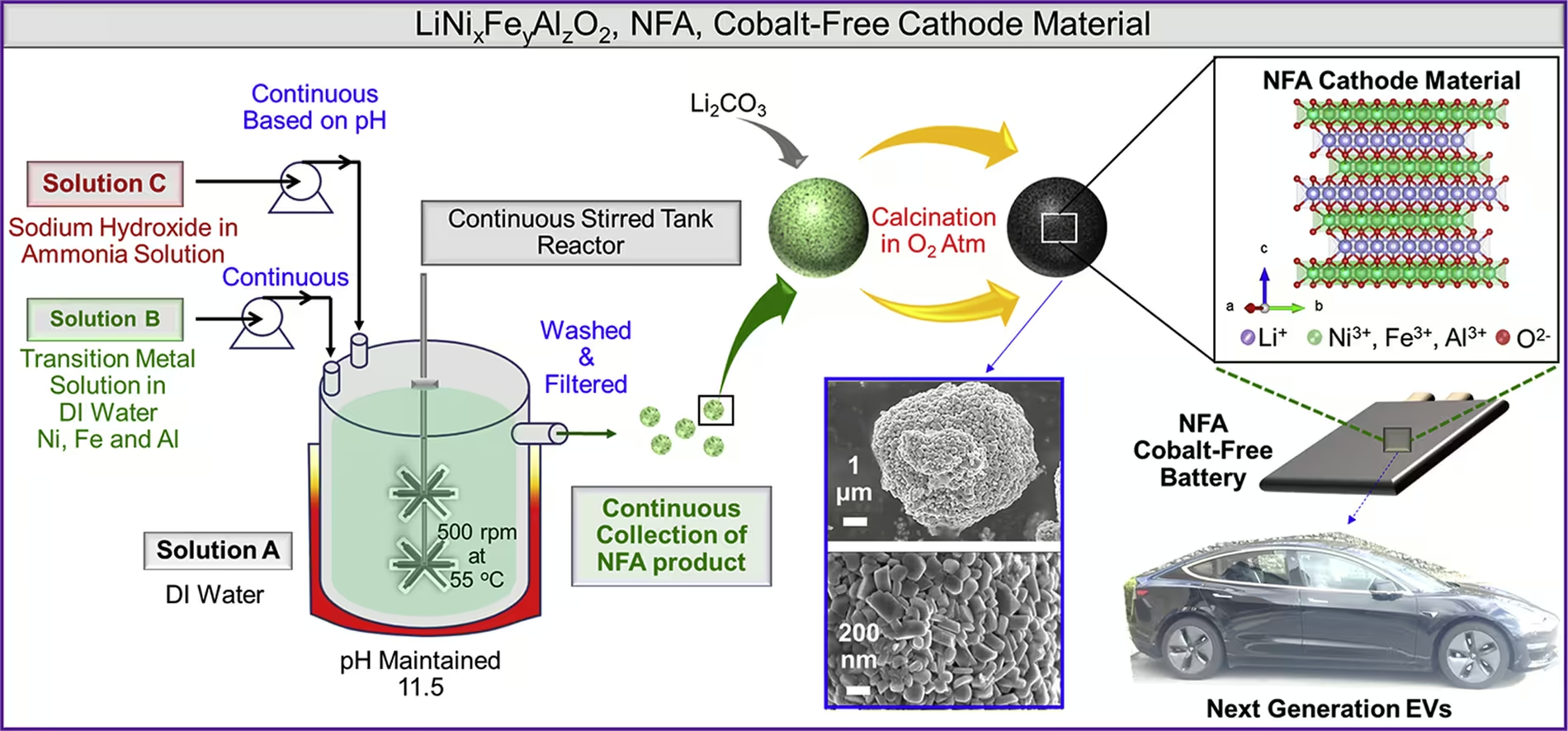

- Battery cell chemistry: NCM 811

- Battery cell maker: CATL

- TMS: liquid-cooling

The math points to battery cells with around 117 Ah, but unfortunately we don’t have important data like the weight or volume to determine their energy density.

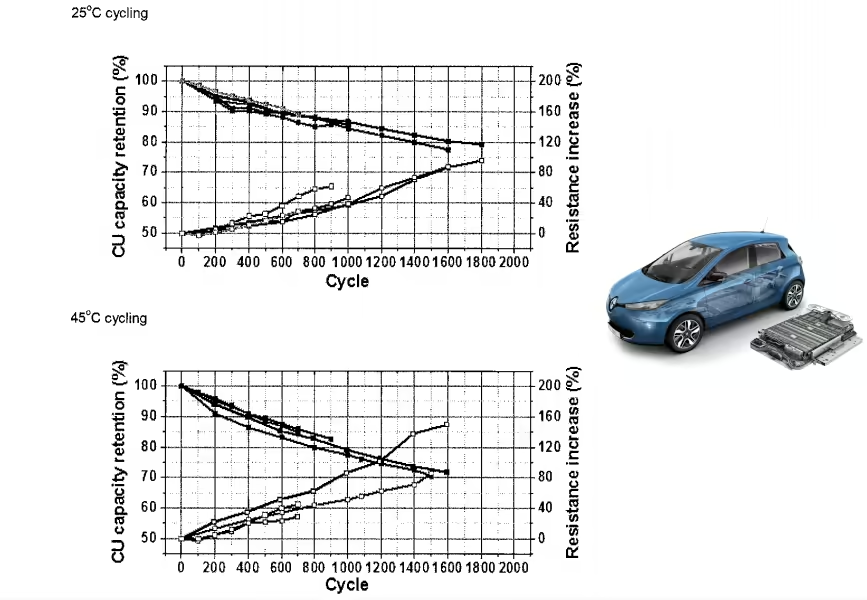

We do however know that the BMW i4 will have different cells, but will also get a 80 kWh battery that weighs roughly 550 kg (145 Wh/kg), which is not impressive considering that simpler batteries made with less energy-dense cobalt-free LFP cells can already surpass 160 Wh/kg.

Using less safe ternary cells (NCM or NCA) requires safety mechanisms that add some weight and volume. With this type of cells it makes sense to use modules, because if some cells catch fire, the module can act as a firewall and prevent it from spreading to other cells.

On the other hand, much safer cobalt-free LFP battery cells are heavier and bigger but won’t catch fire or explode, even if punctured. This means that modules are dispensable and we can assemble lighter and smaller battery packs even if using less energy-dense cells.

Anyway, for its fifth-generation electric powertrains BMW will start with NCM 811 cells from CATL, then in 2021 it will also use cells from Samsung SDI. However, if we look at the sums of money involved, we conclude that CATL will be the main supplier.

The BMW Group will obtain battery cells for its fifth-generation electric drive trains from CATL (order volume: 7.3 billion euros, contract period: 2020 to 2031) and Samsung SDI (order volume: 2.9 billion euros, contract period: 2021 to 2031).

More info:

https://www.press.bmwgroup.com/global/article/detail/T0310696EN/the-first-ever-bmw-ix3