Currently the most energy dense battery packs made with cobalt-free LFP (LiFePO4) cells in China are being used by electric buses.

Yutong electric buses powered by CATL’s LFP battery cells hold the current record with an impressive figure of 161,29 Wh/kg at the battery pack level. This means that at the battery cell level CATL already managed to surpass 190 Wh/kg…

It comes as a nice surprise after the disappointing energy density figure of 125 Wh/kg achieved by the Tesla Model 3 with CATL’s LFP battery cells.

However, to be fair, it’s important to understand that LFP battery cells can be optimized for energy density or power density. It seems that electric buses are getting the variant optimized for energy density while Tesla is getting the variant optimized for power density, which makes sense when we want fast charging rates and super fast acceleration.

Now let’s see a small list of some interesting electric buses with LFP batteries available in China.

- Brand: Yutong

- Model: ZK6126BEVG5E and ZK6126BEVG5L

- Length: 12 m

- Range: 675 km (419 miles)

- Capacity: 350,07 kWh

- Energy density: 161,29 Wh/kg

- Brand: Yutong

- Model: ZK6816BEVG6

- Length: 8,145 m

- Range: 400 km (249 miles)

- Capacity: 175,03 kWh

- Energy density: 161,29 Wh/kg

- Brand: Yutong

- Model: ZK6856BEVG5

- Length: 8,545 m

- Range: 390 km (242 miles)

- Capacity: 175,03 kWh

- Energy density: 161,29 Wh/kg

- Brand: Yutong

- Model: ZK6816BEVG3

- Length: 8,145 m

- Range: 400 km (249 miles)

- Capacity: 175,03 kWh

- Energy density: 161,27 Wh/kg

- Brand: Yutong

- Model: ZK6856BEVG3

- Length: 8,545 m

- Range: 390 km (242 miles)

- Capacity: 175,03 kWh

- Energy density: 161,27 Wh/kg

- Brand: Geely

- Model: DNC6120BEVG8

- Length: 12 m

- Range: 565 km (351 miles)

- Capacity: 338,4 kWh

- Energy density: 161,27-160,43 Wh/kg

- Brand: Jinlong United Automotive Industry (Suzhou)

- Model: KLQ6106GAEVN5

- Length: 10,49 m

- Range: 595 km (370 miles)

- Capacity: 303,4 kWh

- Energy density: 161,27-160,43 Wh/kg

- Brand: Shenlong

- Model: SLK6125UBEVP1

- Length: 11,995 m

- Range: 570 km (354 miles)

- Capacity: 326,73 kWh

- Energy density: 161-160 Wh/kg

- Brand: Dongguan Zhongqi Hongyuan Automobile

- Model: KMT6119HBEV

- Length: 10,995 m

- Range: 510 km (317 miles)

- Capacity: 303,4 kWh

- Energy density: 161-160 Wh/kg

- Brand: Yaxing

- Model: JS6108GHBEV30

- Length: 10,5 m

- Range: 501 km (311 miles)

- Capacity: 303,4 kWh

- Energy density: 160,85 Wh/kg

The range is measured at an unknown constant speed, but considering that some of these electric buses are for urban use and have a maximum speed of 69 km/h (43 mph) it can’t be high…

Notice that the list above is just a small sample I made, on MIIT’s (Ministry of Industry and Information Technology of the People’s Republic) catalog you can find hundreds of different models and some of these electric buses are already being exported to Europe.

By improving #battery pack structure and configuration technique we managed to build 160 Wh/kg pack. We are moving towards mass production, #Guoxuan says.#China May produced #LFP pack with highest density was #CATL 161.29 Wh/kg delivered to Yutong Bus. pic.twitter.com/NyvqtcordV

— Moneyball (@DKurac) June 16, 2020

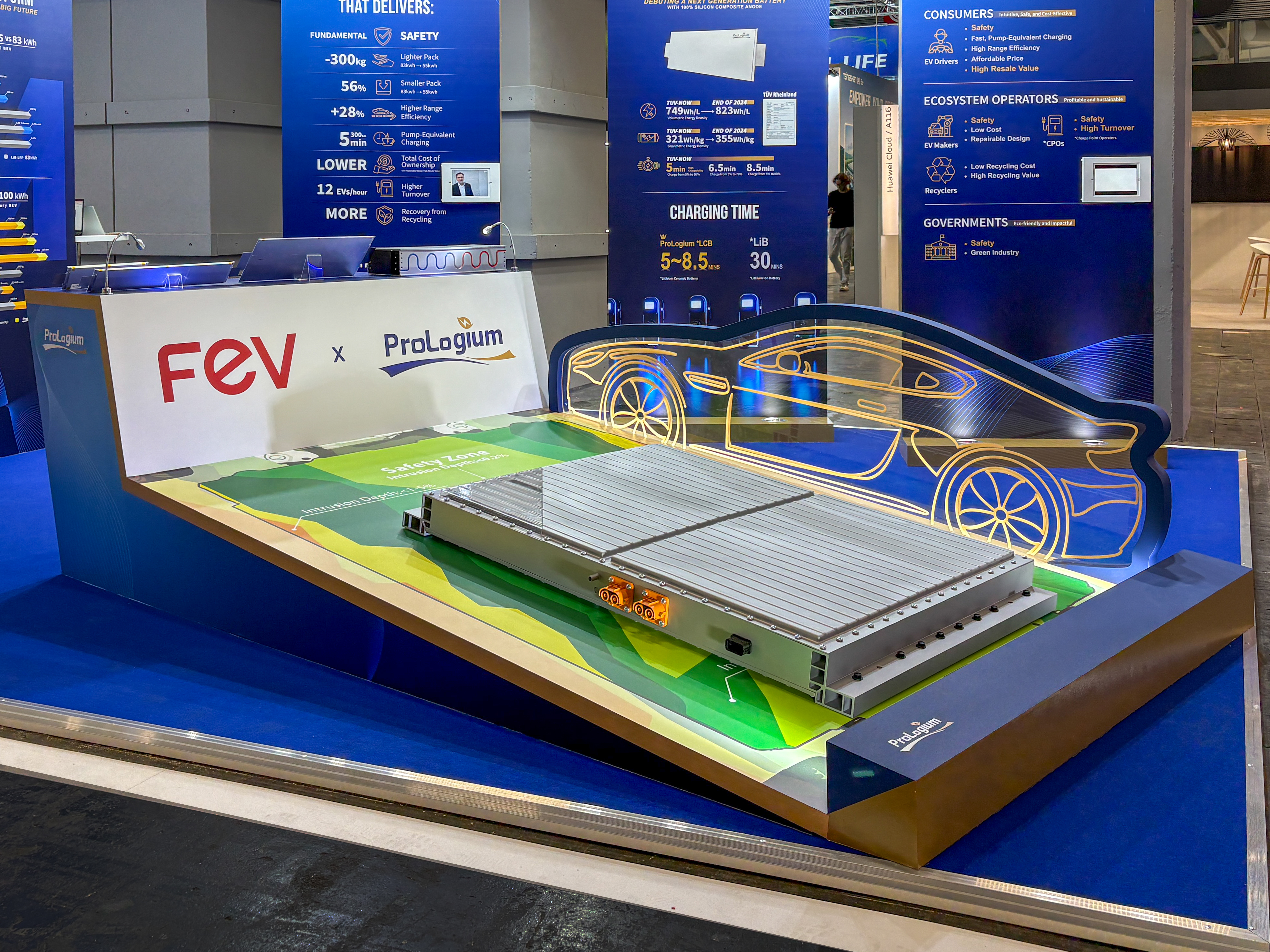

Anyway, CATL might not hold the record for very long. Guoxuan High-Tech is a battery cell maker specialized in LFP chemistry that just received a huge investment from Volkswagen.

This company is already producing LFP battery cells with an energy density of 190 Wh/kg since last year and recently announced to have reached 200 Wh/kg, but is still working on improving performance (cyclability and C-rates).

I’m very curious to see what a module-less CTP (cell-to-pack) battery can achieve with Guoxuan’s latest LFP cells.

A new era for the Chinese electric car market

After electric buses, it’s time for electric cars start getting LFP battery packs with energy densities above 160 Wh/kg. When it happens, they’ll also be eligible for the full subsidy in China without having to use NCM or NCA batteries.

In China, were automakers are really interested in selling electric cars, the quick comeback of LFP batteries now seems inevitable. Only with cobalt-free batteries the production of electric cars can be high enough to completely replace ICE (Internal Combustion Engine) cars.

Moreover, in the near future, with LFMP (high-voltage version of LFP) battery cells we can even reach 240 Wh/kg at the cell level and 200 Wh/kg at the pack level. LFMP chemistry can be as energy dense as LNMO, the cobalt-free chemistry favored by SVOLT that’s scheduled to arrive next year.

What about Europe?

Let’s face it, we also won’t have truly affordable electric cars that compete with ICE cars on price and availability without cobalt-free batteries. We had high hopes for the UpMiiGo electric triplets, but they were short lived.

In Germany…

- Skoda increased the price of the CITIGOᵉ iV and now starts at 25.170 euros.

- SEAT no longer accepts orders for the Mii Electric.

- As for the Volkswagen e-up it has a waiting time so long that makes you give up, it should be named Volkswagen give-up…

Until European automakers start selling electric cars with cobalt-free batteries, they can’t be taken seriously. Production will always be low and prices will be high.

Currently in Europe, most new electric cars have NCM 523 or NCM 622 batteries with an energy density between 140 and 150 Wh/kg. Using cobalt-free CTP batteries that surpass 160 Wh/kg would be an improvement in every area.

We have been waiting for the Chinese invasion for some time, but we also knew that it wouldn’t be successful if Chinese electric cars had nothing new to offer (especially on price and availability). However, now with extremely cheap and safe cobalt-free CTP batteries Chinese electric cars have an unique appeal and their arrival is almost inevitable.

It’ll start with the luxury BYD Han EV in Norway already this year, but soon evolve to a broader offer. With LFP batteries Chinese electric cars can reach price-parity with ICE cars without the need of subsidies.

For example, if BYD decided to replace the 32,2 kWh NCM battery of the BYD e1 with a cobalt-free CTP battery and sell it for 15.000 euros before subsidies worldwide, it could be the modern-day people’s car. Seriously BYD, just do it!

Anyway, when it comes to electric buses Chinese automakers already dominate the European market, we’ll see how long will it take them to accomplish the same with electric cars. Meanwhile, European automakers will keep fighting electric cars and then wonder why suddenly Chinese automakers toke over…

DIY (Do-It-Yourself) projects

Prismatic LFP battery cells were always very tempting to use in personal or academic projects. They are easy to get, durable, safe, powerful and extremely simple to assemble with screw terminals.

In the old days, the best we could get were heavy cells with energy densities around 90-100 Wh/kg from cell makers such as CALB or Thunder Sky. Today we can easily buy much better LFP battery cells with energy densities of 172 Wh/kg and 349 Wh/L, which is very similar to what we get with the much more expensive NCM 111 battery cells from Samsung SDI (174 Wh/kg and 352 Wh/L).

Assembling prismatic battery cells that have screw terminals is as easy as playing with LEGO bricks. We can connect 4 cells in series to assemble an ordinary 12 V battery, 8 cells for a 24 V or 16 cells for a much respectable 48 V battery. I really think that DIY projects will grow considerably with the current evolution of prismatic LFP battery cells.

Today you can already notice a sudden increase in YouTube videos from people that assembled LFP battery cells to replace the 12 V lead-acid battery in their cars or made a 48 V ESS (Energy Storage System) that costed a fraction of a Tesla Powerwall.

Anyway, what do you think? Is cobalt-free CTP batteries the technology that was missing to make electric cars mainstream?

More info:

https://www.d1ev.com/news/shuju/101280

https://en.yutong.com/products/new-energy-ehicles/

https://medium.com/@moneyballr/lfp-tesla-model-3-nothing-to-see-here-8c241ef38399

https://academic.oup.com/nsr/advance-article-pdf/doi/10.1093/nsr/nwaa068/33097434/nwaa068.pdf

http://www.gotion.com.cn/news/company.html

https://www.shanghai-electric.com/group_en/c/2019-08-12/556943.shtml