Large battery cells… why now?

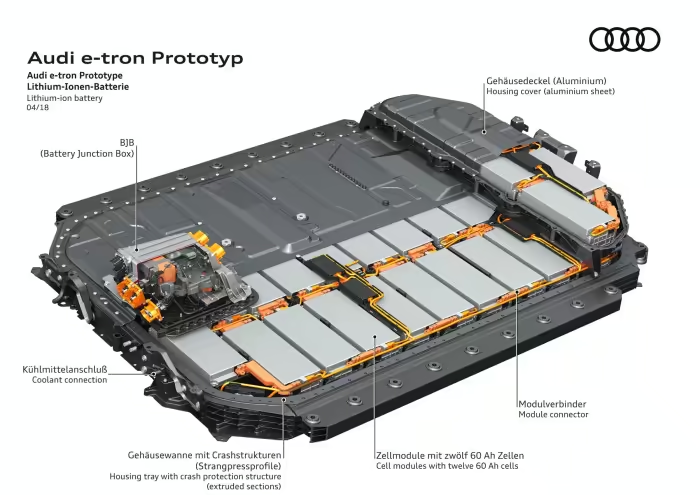

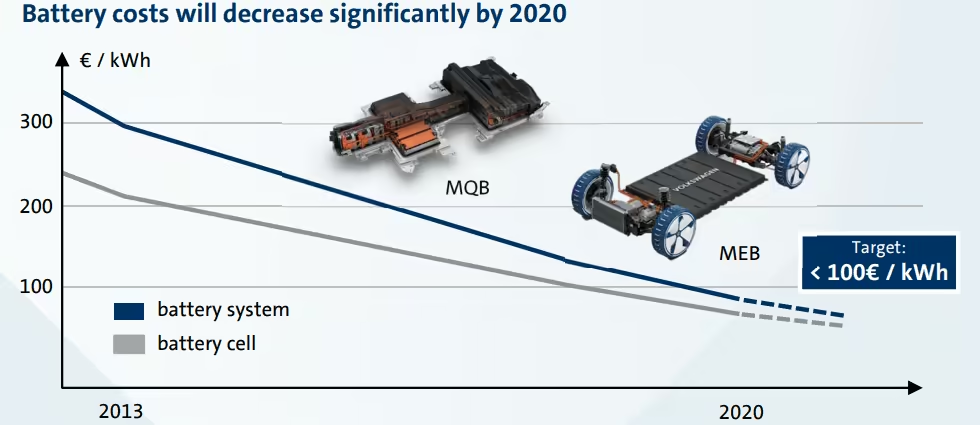

Simpler battery packs made with fewer and larger battery cells weren’t possible with compromised platforms like MQB, however in skateboard platforms like MEB - specially made for electric cars -, they are not only possible, they are what makes sense.

If you’re wondering why Tesla is still using thousands of tiny cylindrical battery cells to assemble complex battery packs, it’s because when the automaker introduced the Roadster in 2008, high energy density battery cells were only available in that format (mostly used in laptops).

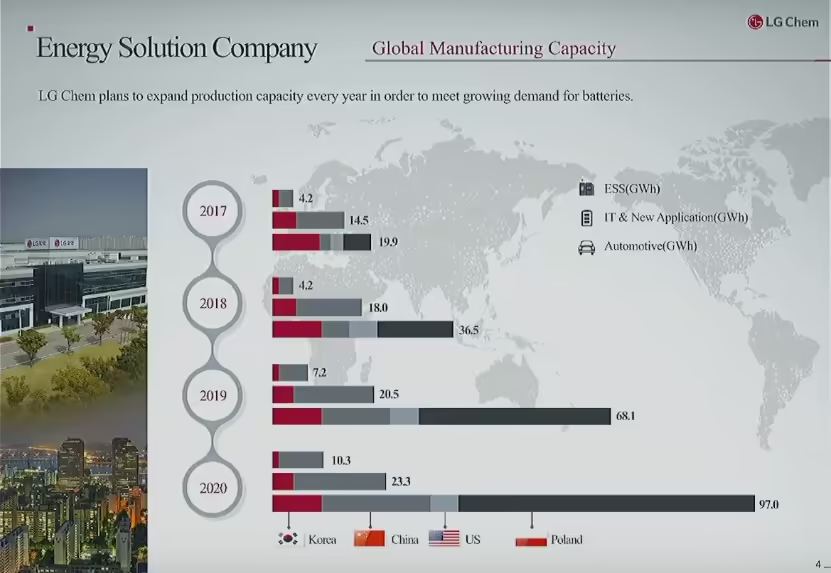

Only in late 2016, high energy density battery cells started to be available in pouch format, like the LGX E63 made by LG Chem.

In 2020, assembling big battery packs with tiny cells doesn’t make sense and I wouldn’t be surprised if Tesla announces a battery pack made with cobalt-free prismatic battery cells in “battery day”. This would be great, not only for Tesla, but also for electric bicycle manufacturers who would benefit from an immediate increase of cylindrical cells available on the market.

Anyway, this article isn’t about Volkswagen or Tesla, it’s about the LFP cobalt-free prismatic battery cell used in BYD Blade Battery. Let’s see its specs and potential.

BYD Blade battery cell specs

- Capacity: 202 Ah

- Nominal voltage: 3,2 V

- Max charging voltage: 3,65 V

- Energy: 646,4 Wh

- Length: 905 mm

- Height: 118 mm

- Width: 13,5 mm

- Volume: 1,442 L

- Volumetric energy density: 448 Wh/L

- Weight: 3,92 kg (estimation)

- Gravimetric energy density: 165 Wh/kg (estimation)

- Chemistry: LiFePO4 (LFP)

Unfortunately I couldn’t find the weight of this cell. However, according to the MIIT (Ministry of Industry and Information Technology) catalog the gravimetric energy density at the battery pack level is 140 Wh/kg, which means 165 Wh/kg at cell level (considering a GCTP of 85 %) and a weight around 3,92 kg.

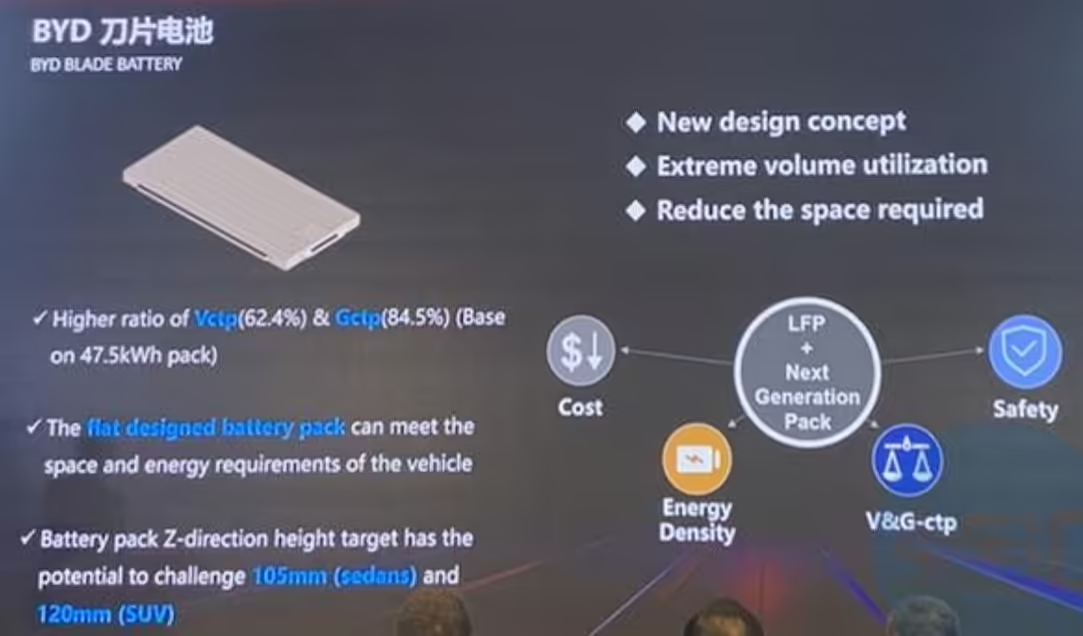

BYD Blade Battery is a module-less CTP (cell-to-pack) battery pack. Without modules, the long prismatic battery cells connected in series are put in an array and then inserted into a battery pack, making it as simple as possible.

The simplicity of the CTP technology helps to achieve a good energy density at the battery pack level, even if the energy density of the cells isn’t amazing.

Now let’s see the specs of a BYD Blade Battery prototype.

BYD Blade battery pack specs (prototype)

- Cells: 92

- Capacity: 202 Ah

- Nominal voltage: 294,4 V

- Max charging voltage: 340,4 V

- Energy: 59,5 kWh

- Volume: 213 L

- Volumetric energy density: 280 Wh/L

- VCTP (Volumetric cell-to-pack ratio): 62,41 %

- Weight: 427 kg (estimation)

- Gravimetric energy density: 139 Wh/kg (estimation)

- GCTP (Gravimetric cell-to-pack) ratio: 84,5 % (estimation)

With standard battery packs assembled with modules, on average the VCTP is 40 %, which means that the volume of the active material (cells) only represents 40 % of the total volume of the battery.

Real applications

The first electric car to use the BYD Blade Battery is the BYD Han EV that’ll be available with two battery capacities (65 and 77 kWh).

The 65 kWh battery pack will give a NEDC range of 506 km (314 miles), which in WLTP should be around 380 km (236 miles).

My guess is that this battery pack is made with 101 or 102 cells.

- 101 cells: 65,3 kWh (101 x 3,2 V x 202 Ah)

- 102 cells: 65,9 kWh (102 x 3,2 V x 202 Ah)

The 77 kWh battery pack will give a NEDC range of 605 km (376 miles), which in WLTP should be around 454 km (282 miles).

My guess is that this battery pack is made with 120 cells.

- 120 cells: 77,6 kWh (120 x 3,2 V x 202 Ah)

The BYD Han EV is a long (4.980 mm) electric car, aimed to be an alternative to the Tesla Model S.

This leaves us with a question…

Can the BYD Blade Battery be used in smaller electric cars?

The BYD Han EV with its long wheelbase (2.920 mm) has no problem to accommodate a long battery. However, it’s interesting to know if a smaller electric car could also accommodate a BYD Blade Battery.

Let’s see how much space does the BYD Blade Battery use.

65 kWh battery pack (cells only)

- Cells: 102

- Capacity: 202 Ah

- Nominal voltage: 326,4 V

- Energy: 65,9 kWh

- Length: 1.377 mm

- Width: 905 mm

- Height: 118 mm

- Volume: 147 L

- Weight: 400 kg (estimation)

If we consider a VCTP of 62,41 %, the battery pack’s total volume is around 236 L. As for the battery’s weight it should be around 468 kg if we consider a GCTP of 85,5 %.

77 kWh battery pack (cells only)

- Cells: 120

- Capacity: 202 Ah

- Nominal voltage: 384 V

- Energy: 77,6 kWh

- Length: 1.620 mm

- Width: 905 mm

- Height: 118 mm

- Volume: 173 L

- Weight: 470 kg (estimation)

If we consider a VCTP of 62,41 %, the battery pack’s total volume is around 277 L. As for the battery’s weight according to the MIIT catalog it’s 549 kg.

So the answer is yes, a smaller electric car could accommodate a BYD Blade Battery.

For example, the 2020 Chevrolet Bolt EV gets an EPA range of 259 miles (417 km) from a 66 kWh battery whose size is 285 L and weighs 430 kg.

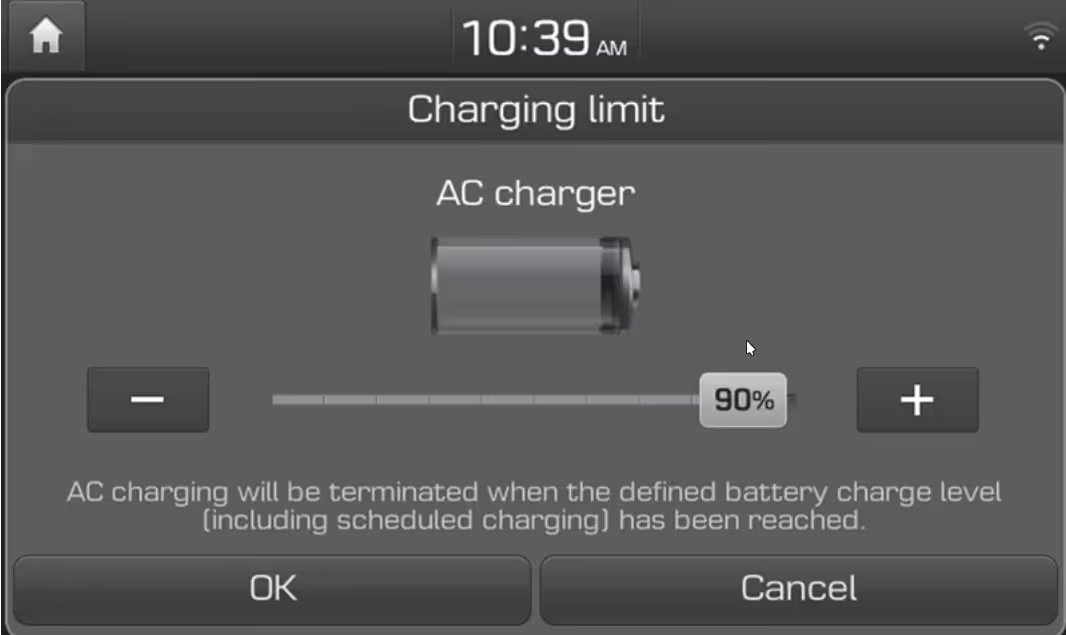

Given the high weight of the 77 kWh BYD Blade Battery, the 65 kWh version would be more suited for the Chevrolet Bolt EV. It would have an EPA range around 250 miles (402 km), but with a good TMS the LFP battery could be fast charged from 0 to 80 % in less than 30 minutes.

Moreover, with 80 euros per kWh at the battery pack level, the battery would cost 5.200 euros.

Summing up

The BYD Blade Battery helps the BYD Han EV to be great electric car and so far it’s the best alternative to the Tesla Model S.

Considering that the BYD Han EV is already set for European launch, Tesla really needs to unveil a cobalt-free battery pack soon…

However, I am more interested in seeing cobalt-free CTP battery packs introduced in smaller electric cars, more suited to European tastes. BYD isn’t alone in this race, CATL and SVOLT also aim to lead in cobalt-free CTP batteries.

Do cobalt-free batteries make electric cars more appealing, or is it something you don’t care about?

More info:

http://www.sum-battery.com/info/byd-blade-battery-acupuncture-experiment-revea-44343117.html

https://insideevs.com/news/424645/byd-han-prices-china/

https://mall.bydauto.com.cn/activity/landingPageCN/D057QG20EG99.htm