In early March I wrote an article about Tesla’s smart strategy in China. In that article I wrote that cobalt-free LFP/LFMP battery packs could already be made for 80 euros per kWh and NCM 811 battery packs for 100 euros per kWh.

Some readers may think that I was being optimistic in that article, but I wasn’t. In fact, I was very cautious with my estimates.

As you can see below, Reuters’ sources now confirm that the cost estimations I presented months ago were actually conservative.

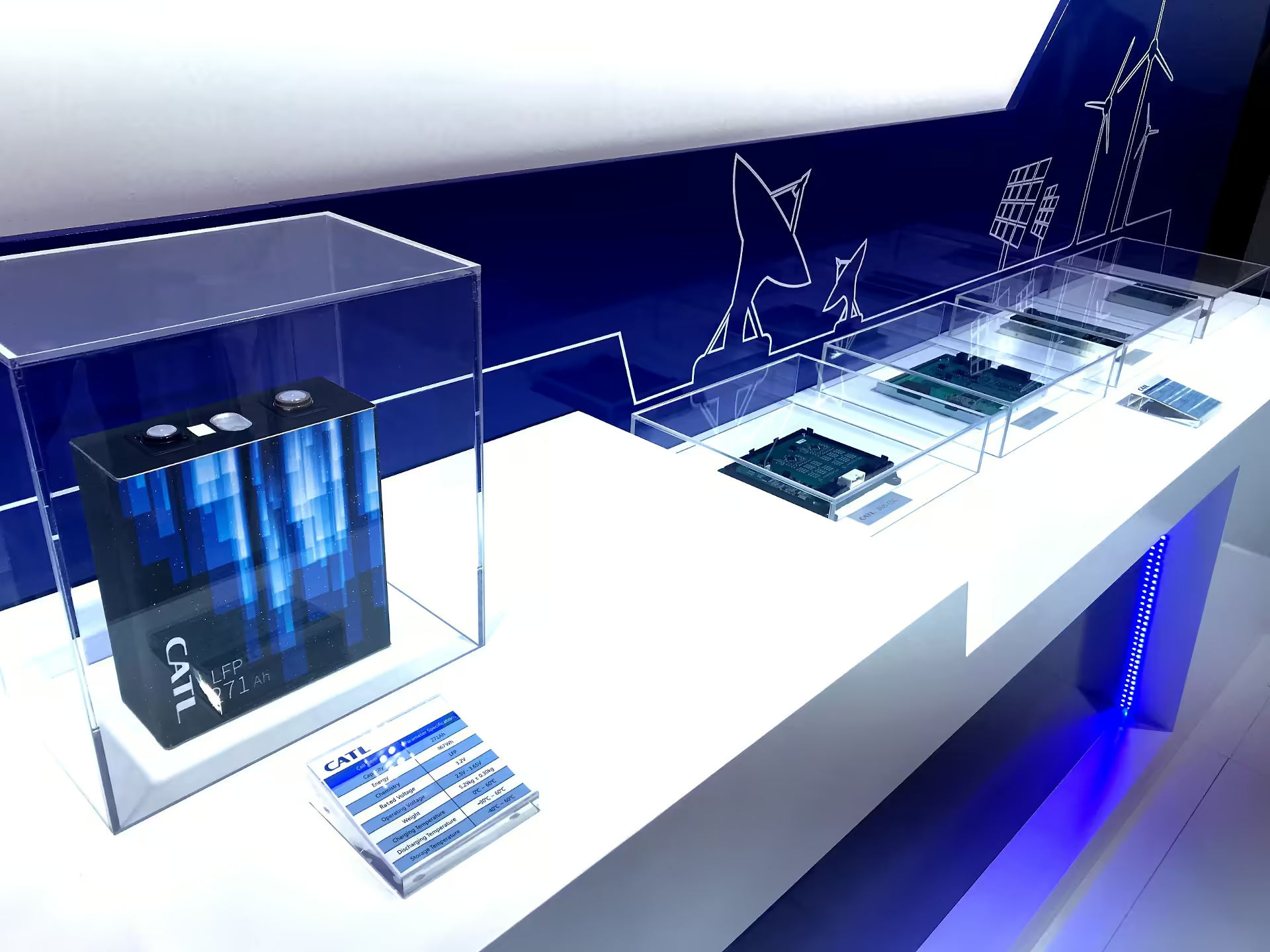

CATL’s cobalt-free LFP/LFMP batteries

- Cost per kWh (cell): 60 USD (55,27 EUR)

- Cost per kWh (battery): 80 USD (73,70 EUR)

Hypothetical 60 kWh battery

- Cost of cells: 3.600 USD (3.316 EUR)

- Cost of complete battery pack: 4.800 USD (4.422 EUR)

Pros

- High power density

- Extremely safe

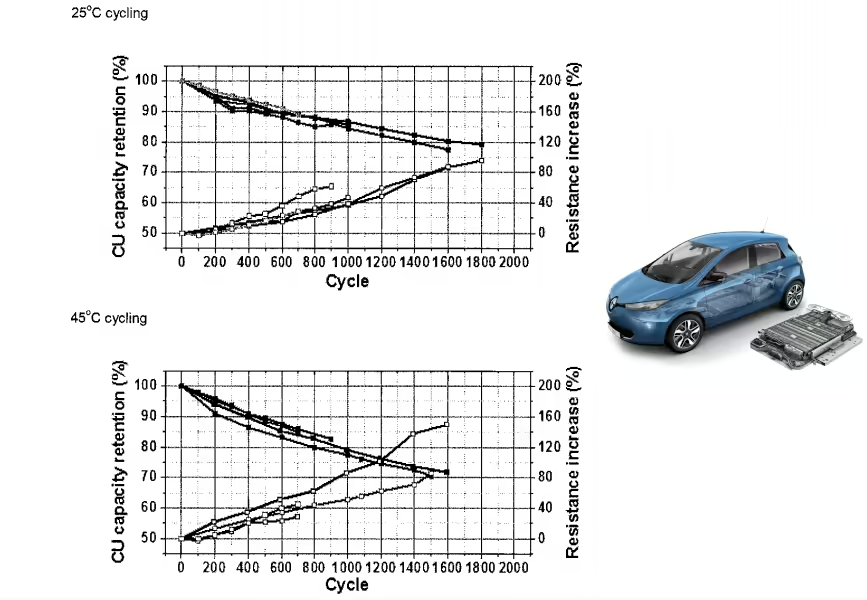

- High cycle life

- Low cost

Cons

- Gravimetric and volumetric energy densities aren’t as high as in NCM and NCA chemistries

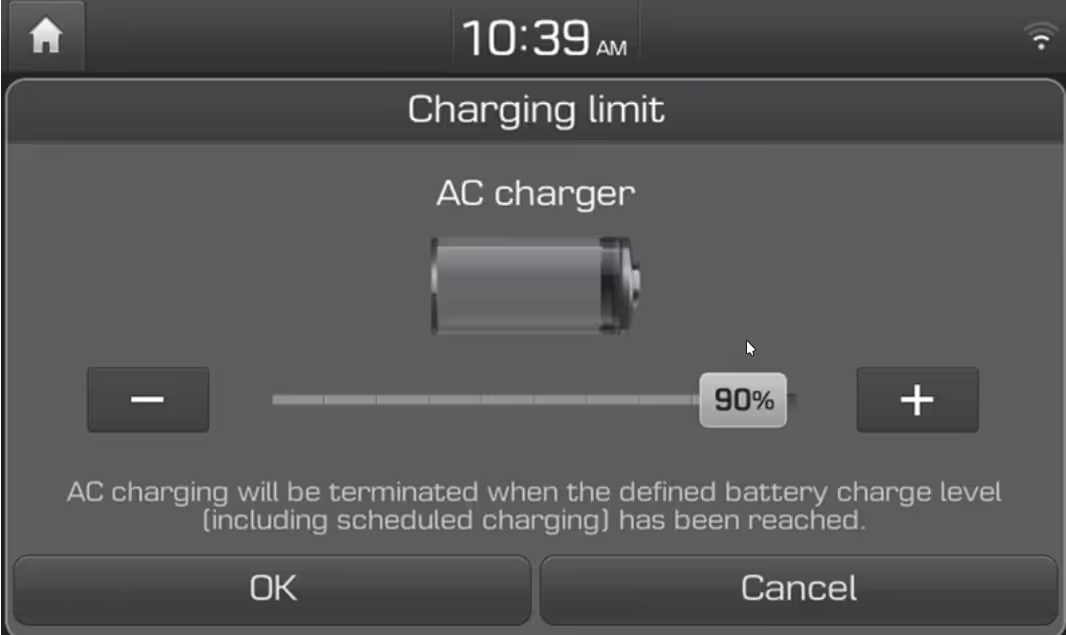

While the energy density of LFP/LFMP batteries isn’t the best, they have high power density and can be charged from 0 to 80 % in less than 20 minutes. The high cycle life also makes them suitable to implement the V2G (Vehicle-to-Grid) technology.

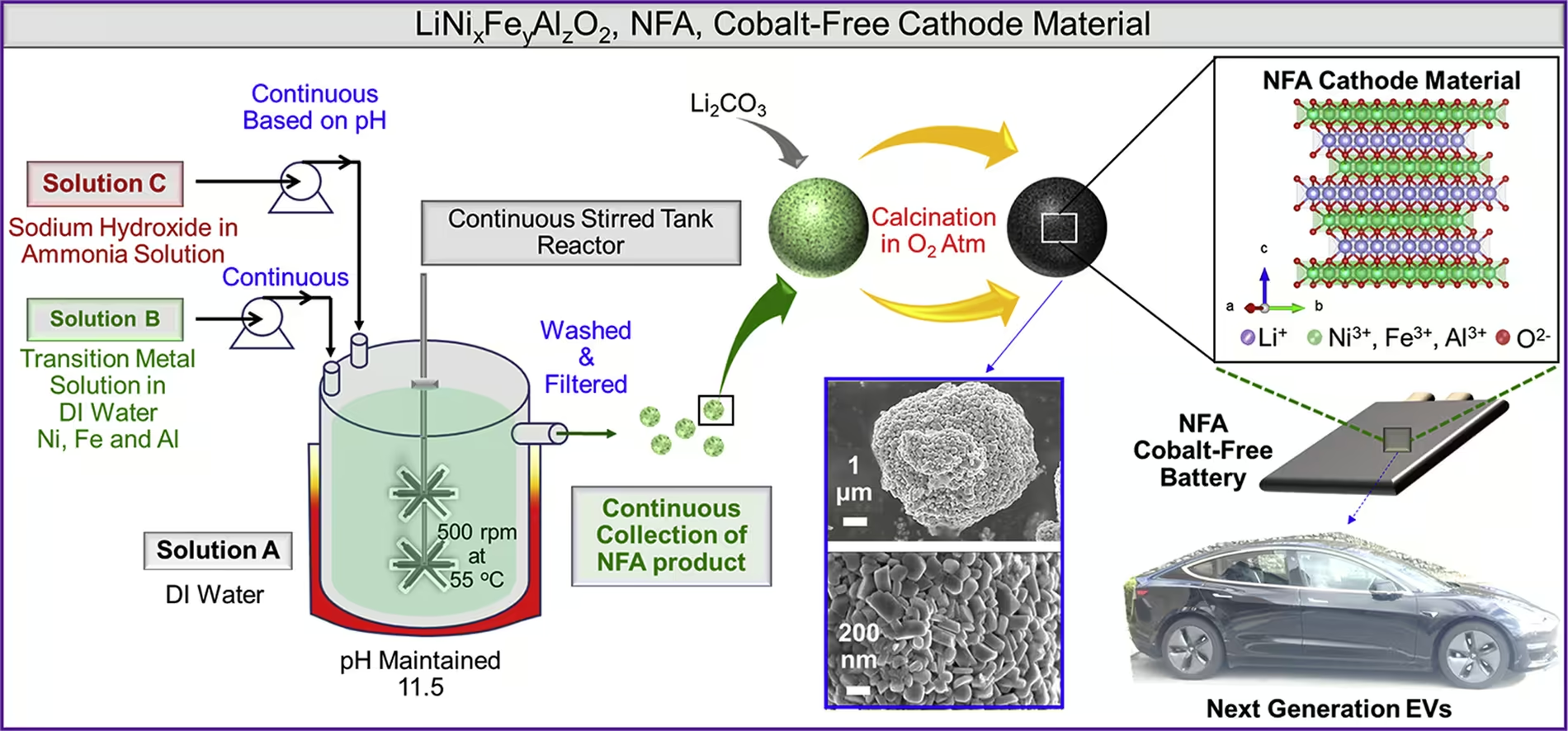

Nonetheless, I still think it’s good idea to not rely on a single battery technology. Nickel-rich battery cells like NCMA and eventually manganese-rich battery cells like NCM 217 will still be important.

Ok, if batteries are not the problem, what about the rest of the electric car?

Considering that electric cars have much less moving parts than their ICE (Internal Combustion Engine) counterparts, the production process is a lot simpler and cheaper. A production line that assembles electric cars requires less machinery, less space, less workers, less energy and less time.

Recently automakers have been using this argument against electric cars. They now admit that electric car production is a lot simpler, therefore it results in increased unemployment… this way they try to scare public policy-makers away from pushing stricter emissions regulations.

Automakers could use this technological breakthrough to increase production quality by giving their workers more resting time instead of threatening them with unemployment… Tired workers are more likely to make mistakes.

Anyway, I started this blog mostly to inform the EV community and public policy-makers on what’s possible with today’s technology and demonstrate that we are being fooled by automakers. The cost of batteries has always been their favorite excuse for delaying the transition to electric cars. Unfortunately this blog has a very small audience and reduced influence.

However, when a large media outlet such as Reuters makes this kind of information available to the public it can be problematic for automakers’ narrative against electric cars. As a result, informed citizens and public policy-makers can push for stricter emissions regulations that favor the transition to electric vehicles.

More info: