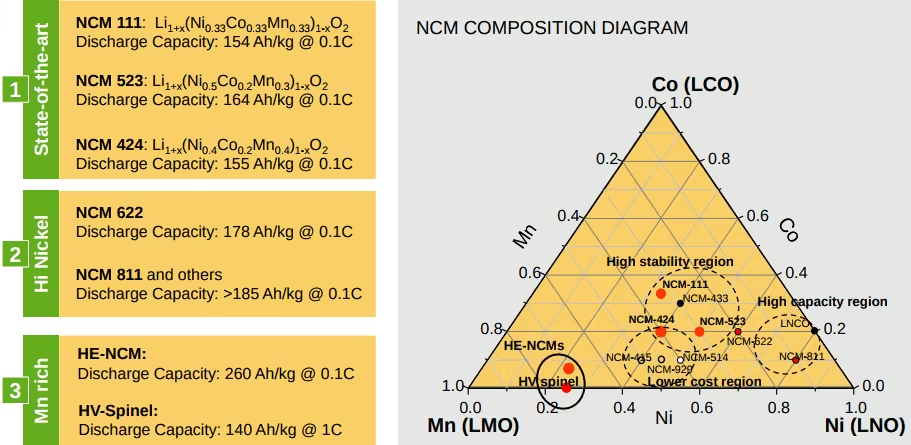

Today most electric cars are powered by batteries with NCM cathodes, whose raw materials besides lithium include nickel, cobalt and manganese.

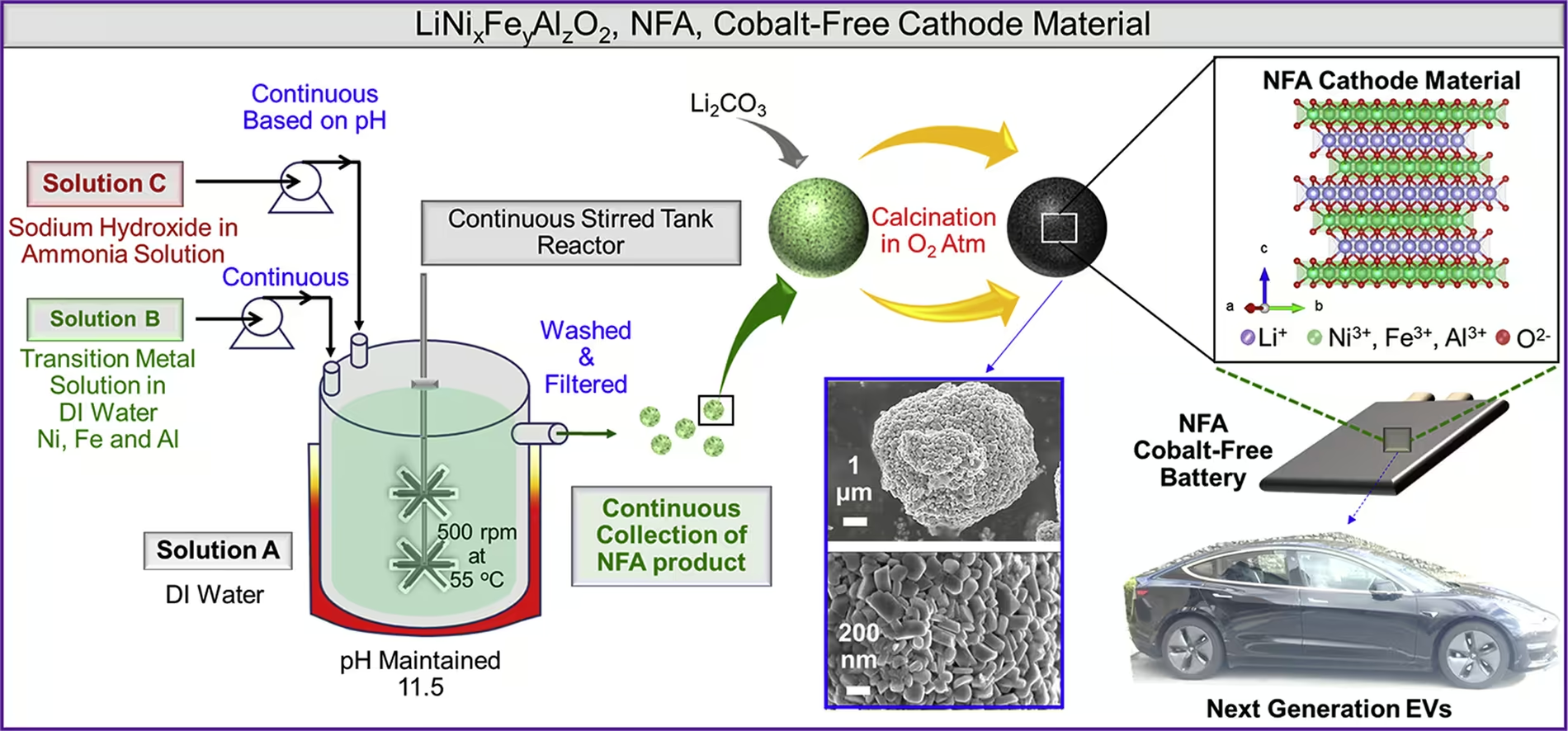

As you probably already know, for the last few years the goal has been to reduce the use of cobalt, which is rare and expensive. Nickel is being used to replace cobalt allowing more energy-dense and cheaper batteries.

- NCM 111: cathode with a Ni:Co:Mn composition ratio of 1:1:1

- NCM 424: cathode with a Ni:Co:Mn composition ratio of 4:2:4

- NCM 523: cathode with a Ni:Co:Mn composition ratio of 5:2:3

- NCM 622: cathode with a Ni:Co:Mn composition ratio of 6:2:2

- NCM 712: cathode with a Ni:Co:Mn composition ratio of 7:1:2

- NCM 811: cathode with a Ni:Co:Mn composition ratio of 8:1:1

However, the next important phase in the development of NCM batteries is to replace nickel with much more abundant and cheaper manganese.

To have an idea let’s see the average market price of these raw materials per ton.

- Cobalt: 27.000 EUR/t

- Nickel: 11.000 EUR/t

- Manganese: 2.000 EUR/t

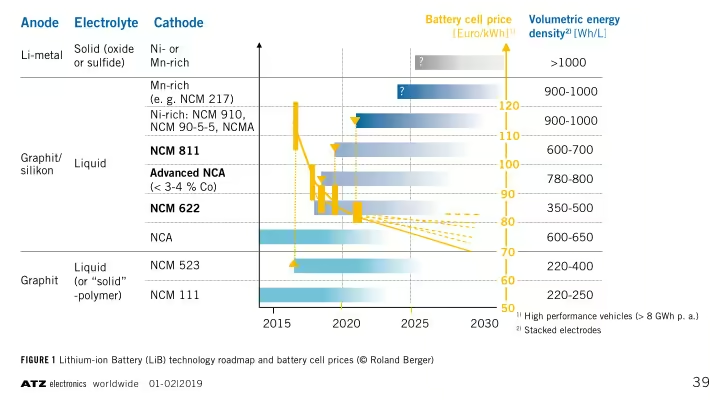

As you can see, regarding costs using manganese makes a lot more sense and for this reason BASF, world’s largest chemical producer expects to start producing cathode active materials for high manganese-content NCM 217 batteries already this year.

With NCM 217 batteries the kWh cost for high-quantity buyers (automakers) is expected to be below 80 euros, which is similar to upcoming cobalt-free LFMP batteries. However, the volumetric energy density of NCM 217 batteries will be much higher (900-1.000 instead of 410-450 Wh/L).

For example the NCM 622 battery of the Hyundai Kona Electric has a total capacity of 67,5 kWh and is made with LGX E63 battery cells that have a volumetric energy density of 500 Wh/L. This means that with NCM 217 cells (1.000 Wh/L) we could double the battery capacity to 135 kWh and maintain the same volume. It would be enough to give the Hyundai Kona Electric a WLTP range superior to 900 km (559 miles)…

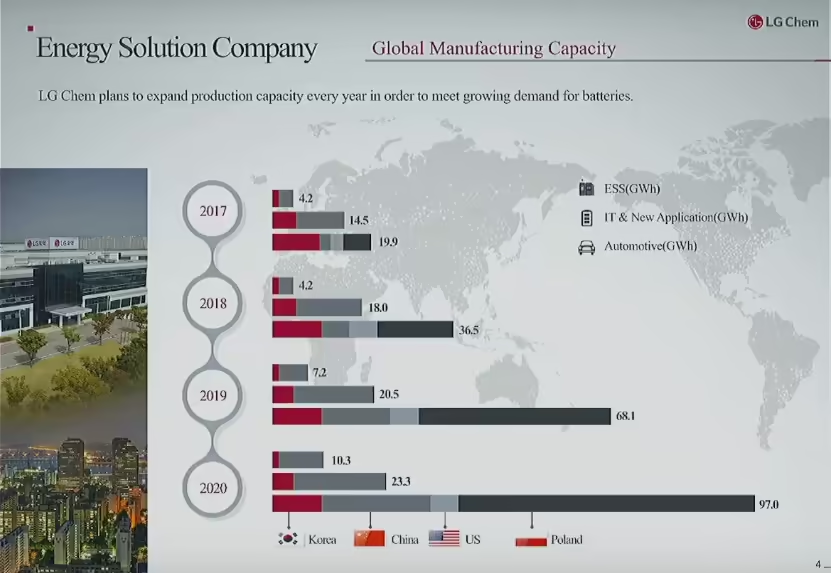

Anyway, while the cathode active materials might be available already this year, it doesn’t mean that battery cell makers will be using them immediately for mass production. Extensive testing is needed before mass production of EV batteries. Therefore, expect the phase 1 (cobalt reduction) to be completed with the introduction of NCMA cathodes in 2021/2022 and the start of phase 2 (nickel reduction) with NCM 217 cathodes one or two years later.

If we really want to know where NCM batteries are heading, we must consider what the world’s largest chemical producer is doing, instead of relying on constant press releases with claims too good to be true from likely scammers trying to lure investors.

More info:

https://catalysts.basf.com/products-and-industries/battery-materials/cathode-active-materials/ncm

https://fkg.se/wp-content/uploads/2019/05/8-BASF-Josef-R-Wuensch.pdf

https://www.energy.gov/sites/prod/files/2014/11/f19/Fetcenko%20-%20Industry%20Partners%20Panel_0.pdf

https://sci-hub.tw/https://link.springer.com/article/10.1007/s38314-018-0092-z

https://sci-hub.tw/https://www.sciencedirect.com/science/article/abs/pii/S0378775319306779

https://www.samsungsdi.com/column/technology/detail/55272.html