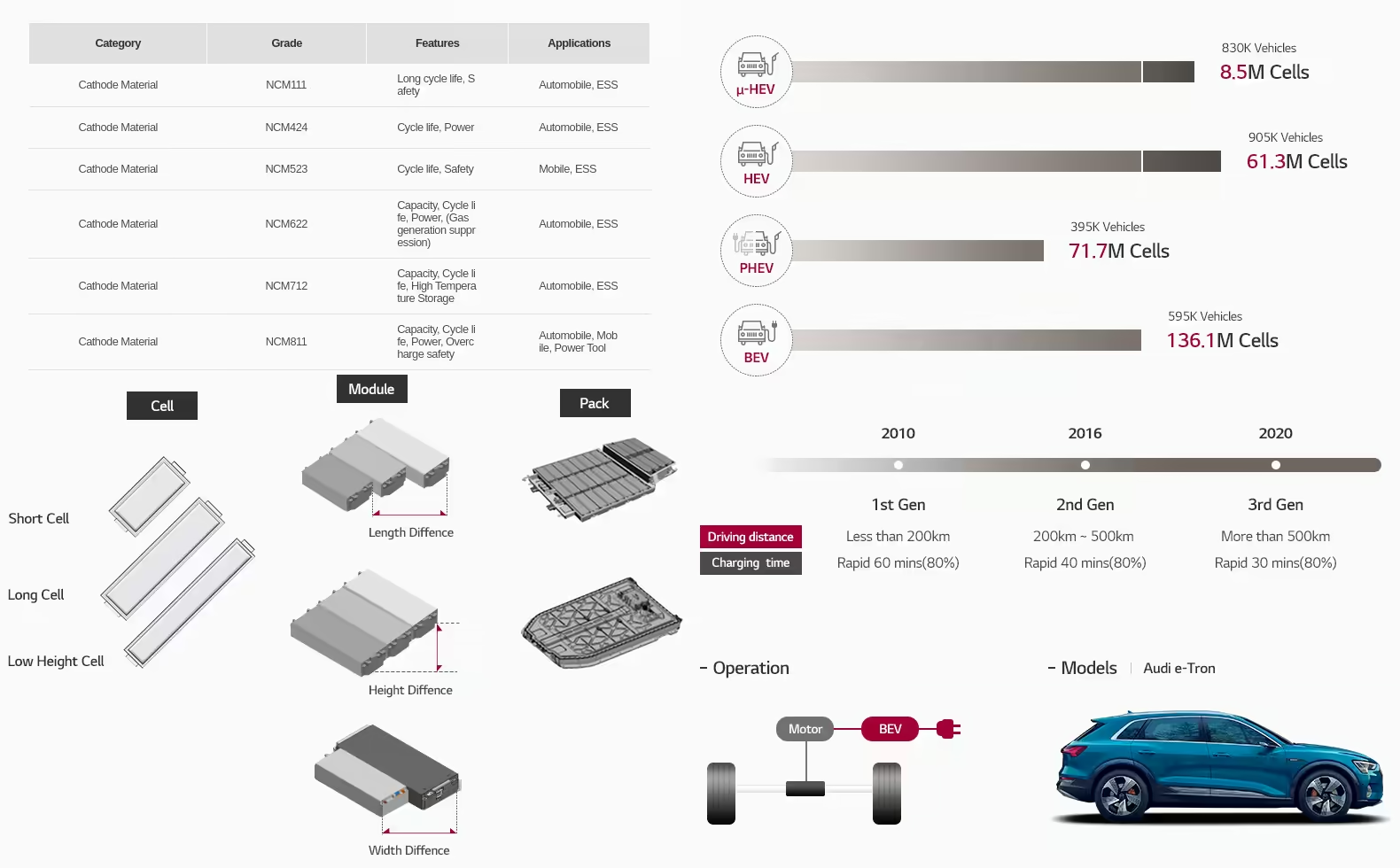

Years ago LG Chem decided that for pouch battery cells it would first replace NCM 622 with NCM 712 cathodes before moving to NCMA in 2022, while reserving the NCM 811 cathode to cylindrical battery cells.

We’re always talking about NCM 811 cathodes and easily forget that NCM 712 battery cells arrived quietly and are already powering electric cars in Europe.

The new generation Renault ZOE was the first electric car in Europe to get the NCM 712 battery cells from LG Chem, but soon others will follow.

By observing what changed in the Renault ZOE, we can estimate possible changes in other electric cars that still use the same LGX E63 battery cells of the old generation Renault ZOE.

Let’s start by observing the changes in the Renault ZOE.

Renault ZOE

Renault ZOE (old ZE 40 battery)

- Total battery capacity: 44,1 kWh

- Usable battery capacity: 41 kWh

- Battery pack weight: 305 kg

- Gravimetric energy density at battery pack level: 145 Wh/kg

- Cells: 192 (96s2p)

- Chemistry: NCM 622

- Manufacturer: LG Chem

- WLTP range: 317 km (197 miles)

Renault ZOE (new ZE 50 battery)

- Total battery capacity: 55 kWh (estimation)

- Usable battery capacity: 52 kWh

- Battery pack weight: 326 kg

- Gravimetric energy density at battery pack level: 169 Wh/kg

- Cells: 192 (96s2p)

- Chemistry: NCM 712

- Manufacturer: LG Chem

- WLTP range: 395 km (245 miles)

The battery capacity increased around 11 kWh, while the weight increased by 21 kg.

Now let’s estimate possible upgrades for electric cars that still use the same LG E63 battery cells of the old generation Renault ZOE, namely the very popular Hyundai IONIQ Electric and Hyundai Kona Electric.

Hyundai IONIQ Electric

Current battery with NCM 622 cells

- Total battery capacity: 40,4 kWh (estimation)

- Usable battery capacity: 38,3 kWh

- Battery weight: 359 kg (without battery heater) and 363 kg (with battery heater)

- Battery energy density: 112,4 Wh/kg (without battery heater) and 111,2 Wh/kg (with battery heater)

- Cells: 176 (88s2p)

- Chemistry: NCM 622

- Manufacturer: LG Chem

- WLTP range: 311 km (193 miles)

Possible battery with NCM 712 cells

- Total battery capacity: 50,4 kWh (estimation)

- Usable battery capacity: 48 kWh

- Battery weight: 378 kg (without battery heater) and 382 kg (with battery heater)

- Battery energy density: 133 Wh/kg (without battery heater) and 132 Wh/kg (with battery heater)

- Cells: 176 (88s2p)

- Chemistry: NCM 712

- Manufacturer: LG Chem

- WLTP range: 392 km (244 miles)

The battery capacity would increase around 10 kWh, while the weight would increase by 19 kg.

Hyundai Kona Electric

Current Long range version with NCM 622 cells

- Total battery capacity: 67,5 kWh (estimation)

- Usable battery capacity: 64 kWh

- Battery weight: 452 kg

- Battery energy density: 149 Wh/kg

- Cells: 294 (98s3p)

- Chemistry: NCM 622

- Manufacturer: LG Chem

- WLTP range: 484 km (301 miles)

Possible Long range version with NCM 712 cells

- Total battery capacity: 84 kWh

- Usable battery capacity: 80 kWh

- Battery weight: 484 kg

- Battery energy density: 174 Wh/kg

- Cells: 294 (98s3p)

- Chemistry: NCM 712

- Manufacturer: LG Chem

- WLTP range: 605 km (376 miles)

The battery capacity would increase around 16,5 kWh, while the weight would increase by 32 kg.

Here is where I have my doubts as it was briefly discussed in the comment section of the previous article.

Recently Hyundai announced that the European-made Kona Electric gets a WLTP range increase from 449 to 484 km. Hyundai explains this 8 % range increase with new more efficient tires, but new tires alone can’t explain all this difference in range and efficiency, 2-3 % maybe, but not 8 %.

Possible explanation number 1

In 2018 Hyundai had to downgrade the WLTP range of the Kona Electric from 470 to 449 km (292 to 279 miles). Therefore, this new increase of WLTP range might be in part explained by new tires, but most of it is probably due to a readjustment to the previous downgrade calculations and not real efficiency gains.

If Hyundai never had to downgrade the previous WLTP range, now an increase of range from 470 to 484 km would represent only 3 % and this could be explained solely by the new tires.

Possible explanation number 2

Another possible explanation is that the European-manufactured Hyundai Kona Electric got better efficiency and range, not only from more efficient tires, but also from a lighter battery pack made with NCM 712 battery cells. If this is the case, it means that Hyundai decided to use the new more energy-dense NCM 712 battery cells not to increase the battery capacity, but instead reduce the weight, size and cost of the battery pack. This weight reduction would give the Hyundai Kona Electric more range, better efficiency, better acceleration, better stopping distance and lower production costs.

I think that the explanation number 1 is more plausible and the European-made Hyundai Kona Electric still uses NCM 622 battery cells. However, If you know the correct answer let us know in the comment section, this one needs good detective work.

Update…

After reading some comments and do the math, I’m now convinced that the 2020 Chevrolet Bolt EV is already using NCM 712 battery cells and that Hyundai could use the same cells in the Kona Electric to keep the current 64 kWh usable battery capacity, while reducing weight, size and cost of the battery pack.

Let’s see what GM managed to do with the Chevrolet Bolt EV.

Chevrolet Bolt EV and Opel Ampera-e

- Total battery capacity: 62,2 kWh

- Usable battery capacity: 58 kWh (variable)

- Battery weight: 435 kg

- Battery energy density: 143 Wh/kg

- Cells: 288 (96s3p)

- Chemistry: NCM 622

- Manufacturer: LG Chem

- EPA range: 383 km (238 miles)

- Total battery capacity: 68 kWh

- Usable battery capacity: 64 kWh (variable)

- Battery weight: 430 kg

- Battery energy density: 158 Wh/kg

- Cells: 288 (96s3p)

- Chemistry: NCM 712 (not confirmed)

- Manufacturer: LG Chem

- EPA range: 417 km (259 miles)

The battery capacity advertised by Chevrolet is neither total nor usable, is something in between…

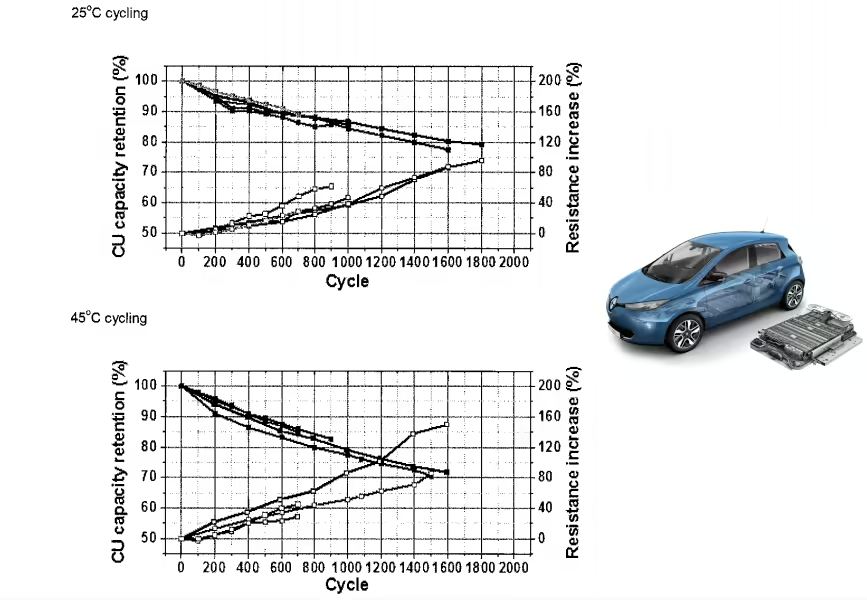

Regarding the new 2020 generation, it is likely that there was a change to NCM 712 battery cells and although the increase in energy density seems minimal, there is an explanation. The 2020 Chevrolet Bolt EV now has the “cold weather battery pack” that according to GM allows 150 % faster DC charging in cold weather.

This “cold weather battery pack” means better insulation and heating of the battery but is likely to result in extra weight. Explaining why the energy density of the battery pack only increased from 143 to 158 Wh/kg, while in the Renault ZOE, the upgrade to NCM 712 battery cells resulted in an energy density increase from 145 to 169 Wh/kg.

If the European-made Hyundai Kona Electric does in fact already have NCM 712 battery cells it also got its weight reduced, I need to check this out.

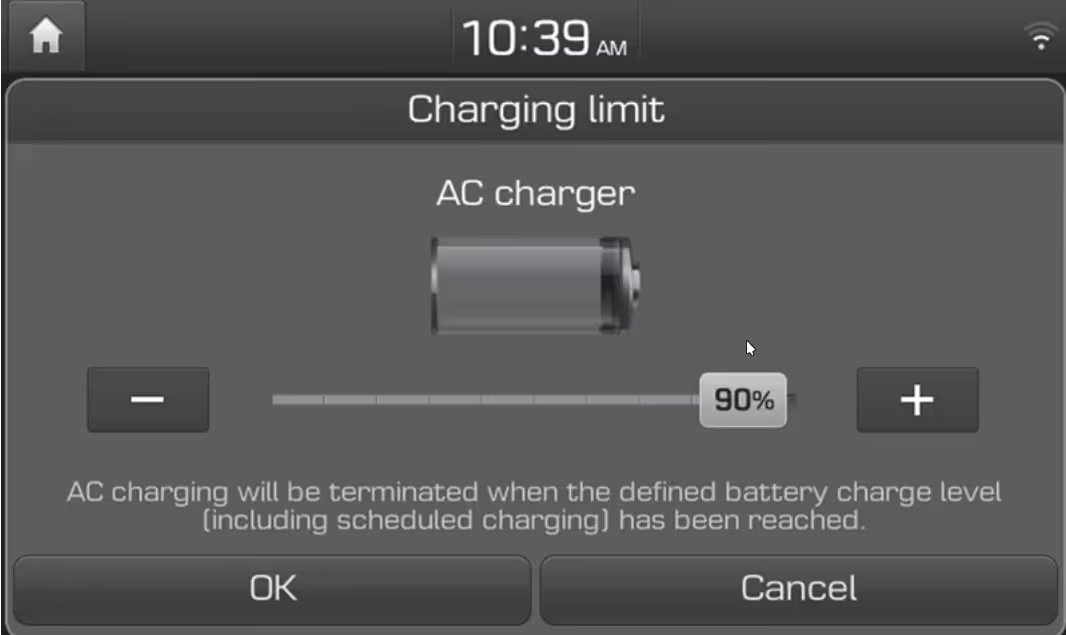

Anyway, as I see it the Hyundai Kona Electric doesn’t need more range than it currently has, for most people price is still the problem, not range. The more energy-dense NCM 712 battery cells should be used to make a lighter, smaller and cheaper battery pack.

As for the Hyundai IONIQ Electric I think that it definitely needs the battery capacity upgrade, not only to basically match the WLTP range of the popular new Renault ZOE, but also to surpass the Peugeot e-208/Opel Corsa-e. Moreover, thanks to its incredible efficiency, even with a smaller battery capacity it would have more range than the Nissan LEAF e+, which gets a WLTP range of 385 km (239 miles) from a big 62 kWh battery.

This article was meant to show you what the battery technology we already have available can achieve. Automakers like Toyota that say they are waiting for the perfect battery (which is an unicorn and will never exist) to finally embrace electric cars, are the ones that want nothing done.

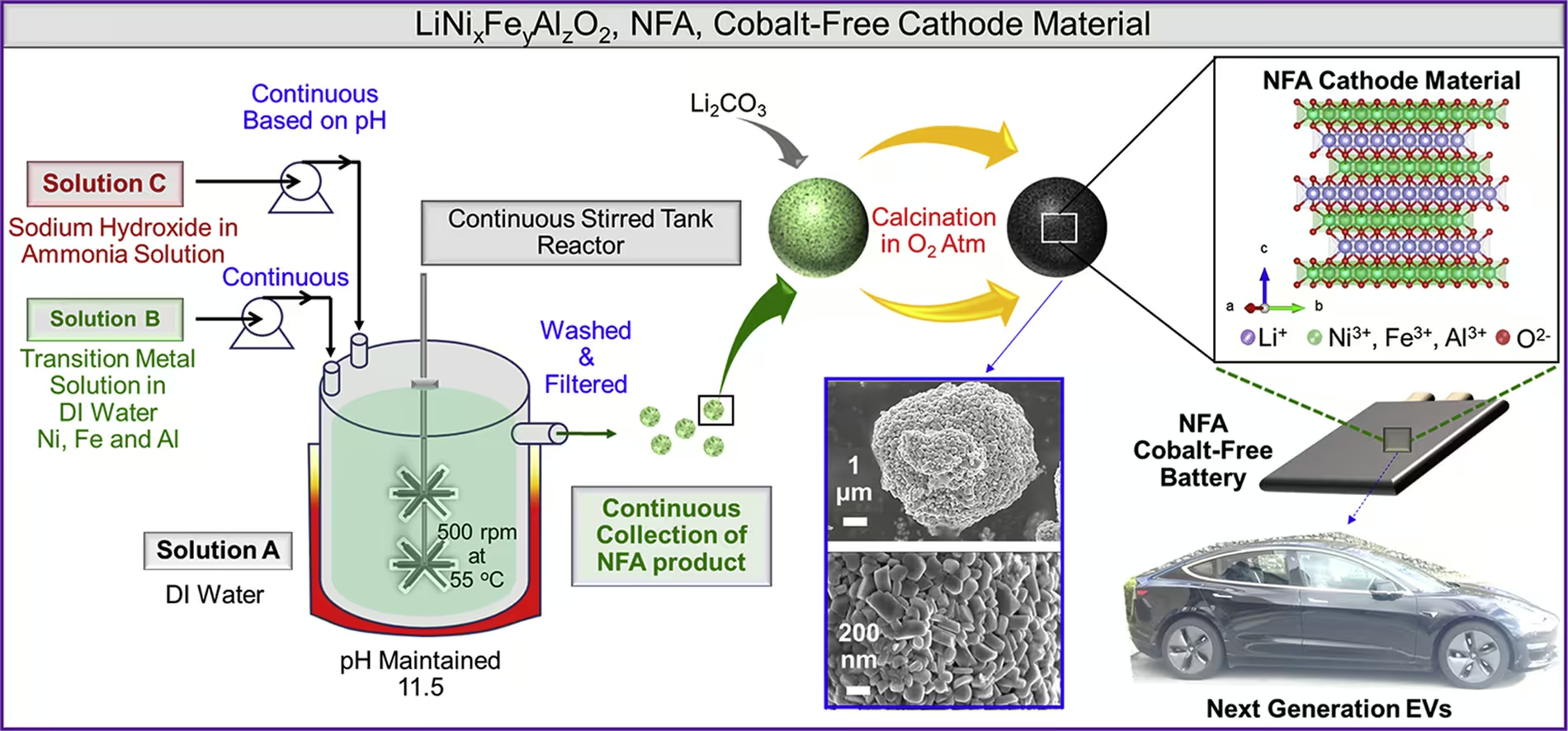

While better things are definitely coming soon - like NCMA and cobalt-free LFMP batteries -, automakers already have the tools to make great electric cars with good range that are affordable.

Moreover, battery technology isn’t the only important thing, automakers also need to focus more on efficiency. The Tesla Model 3 and the Hyundai IONIQ Electric already proved that it really matters.

More info: