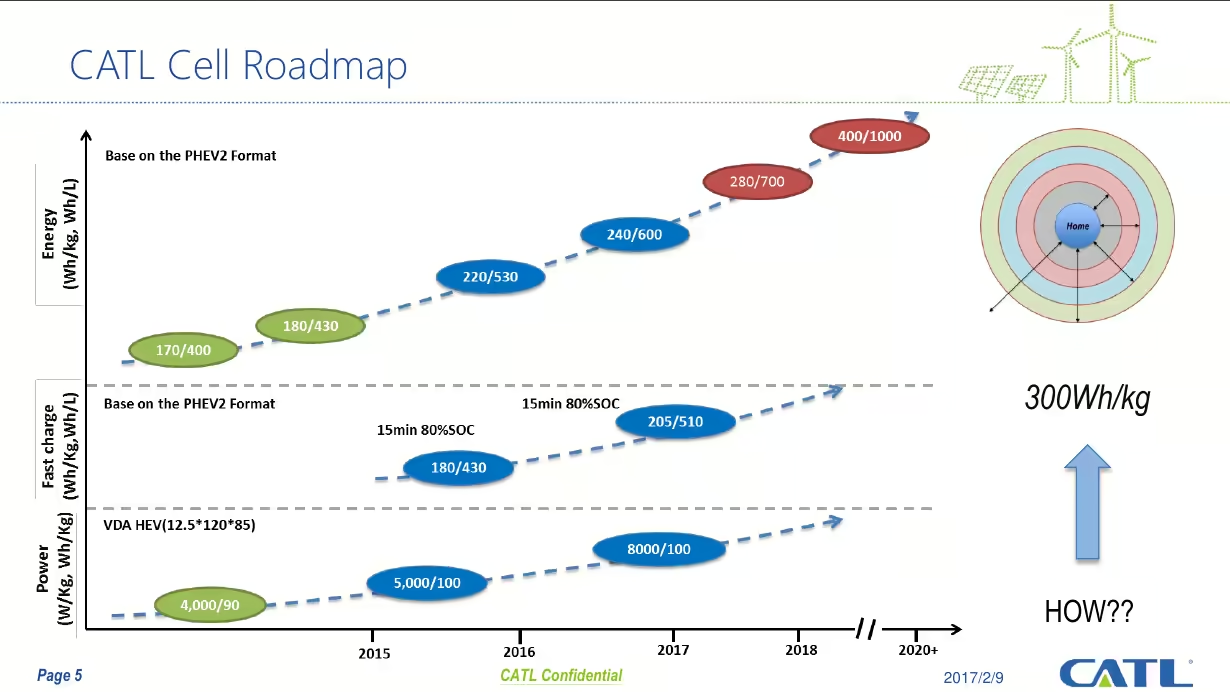

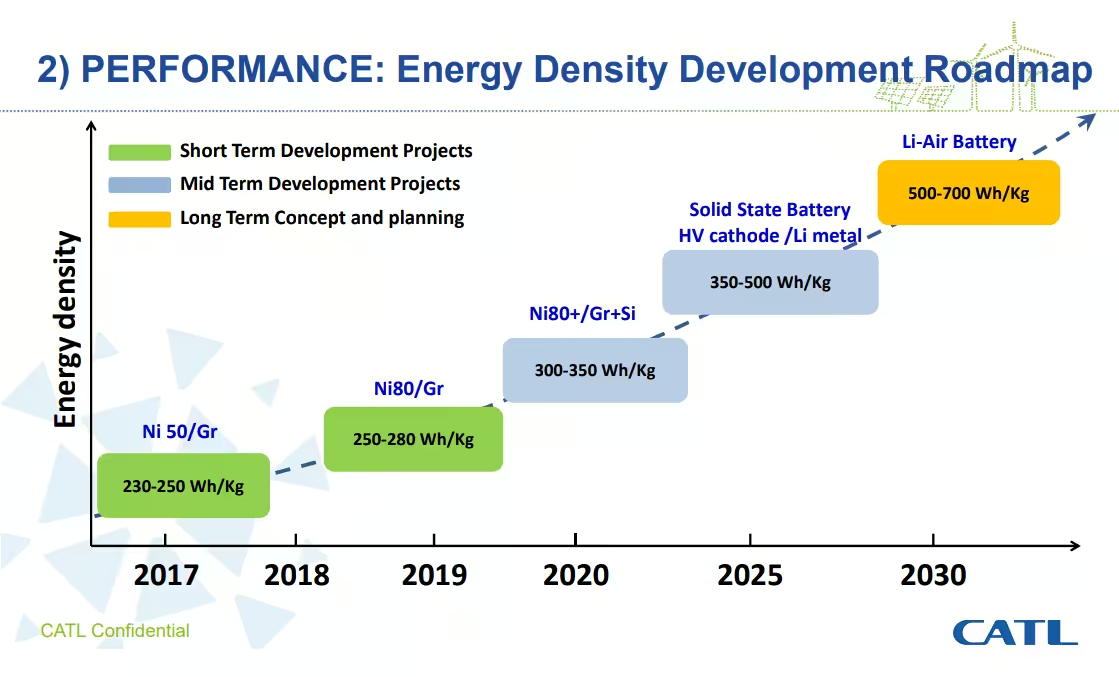

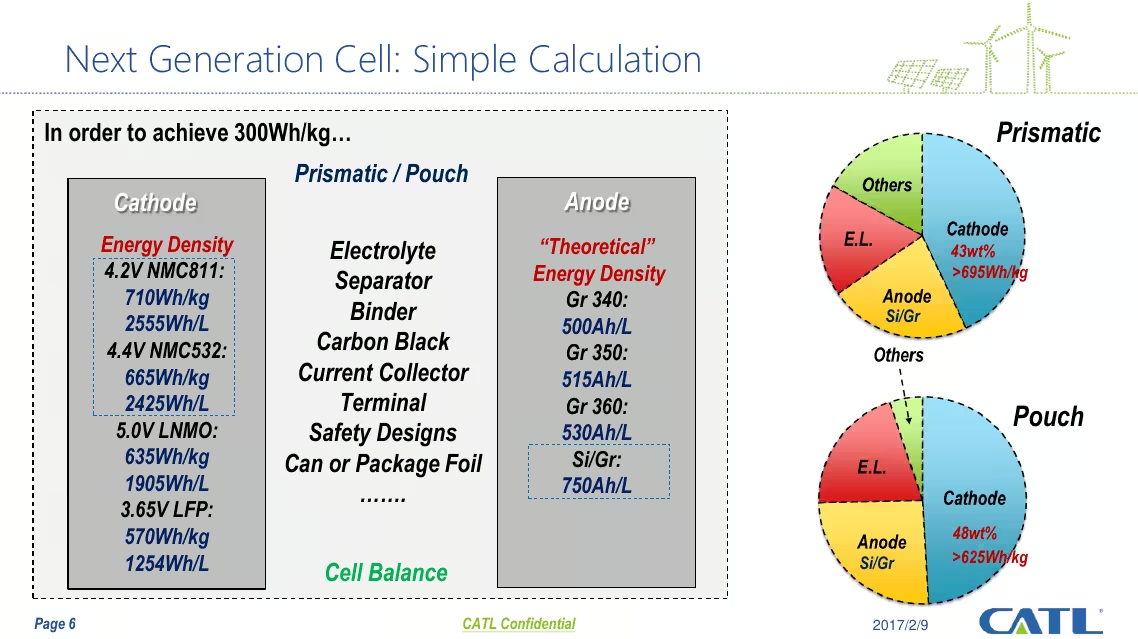

China’s 13th Five-year Plan (2016 to 2020) sets the goals for EV battery cells of reaching an energy density higher than 300 Wh/kg and cost lower than 100 €/kWh. Currently battery cell makers are working to reach or even surpass these objectives.

While Chinese battery cell makers are free to decide how they are going to achieve the goals set by the Chinese Government, NCM 811 battery cells are clearly the way to go. This cathode chemistry allows to reach high energy densities with the use of larger quantities of nickel, while keeping costs low by reducing the amount of cobalt present.

Furthermore the use of hybrid anodes made with graphite and silicon allows to increase the energy density even more than normal graphite cathodes.

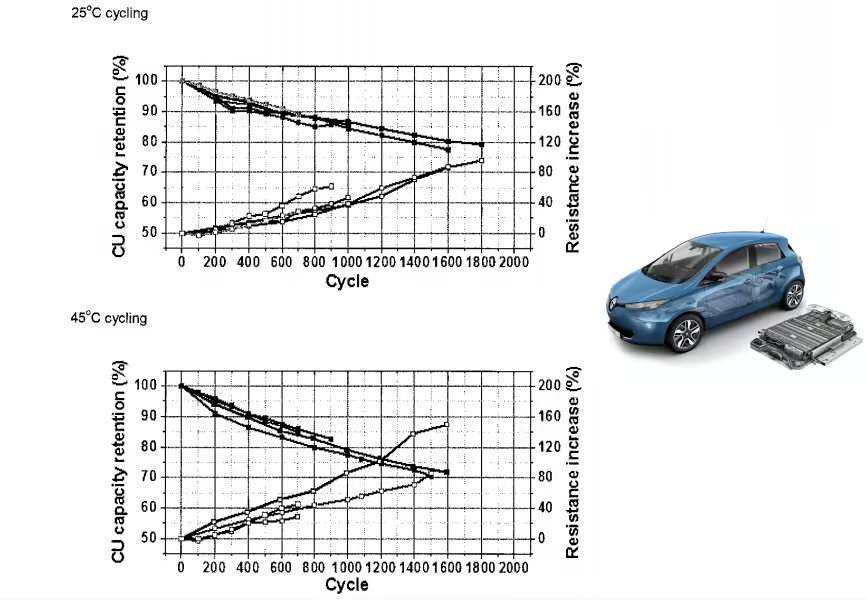

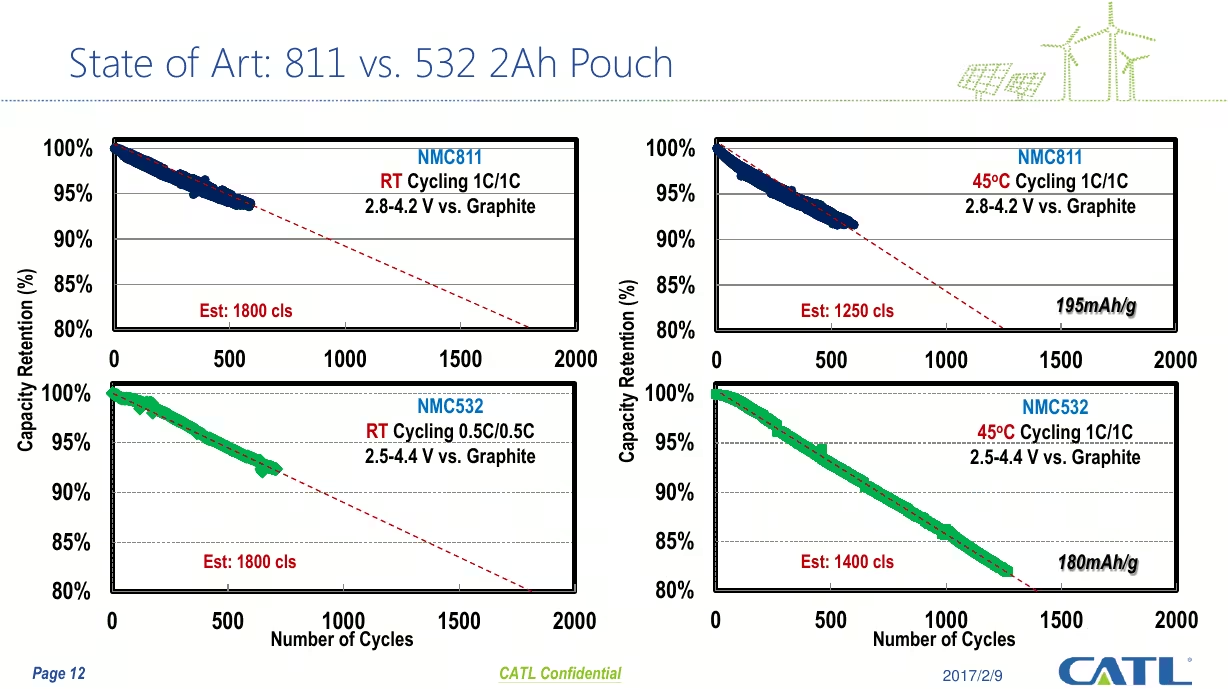

With the introduction of NCM 811 batteries, the use of TMS (Thermal Management Systems) becomes even more important. While at regular temperature (25º C) state of the art NCM 811 battery cells should retain 80 % of their initial capacity after 1.800 charge/discharge cycles, if the temperate increases to 45º C the cycle life drops to 1.250 (31 % less).

Anyway, CATL seems confident to reach the Chinese Government’s goals even before 2020 and introduce a 75 Ah VDA PHEV2 battery cell. If applied today, this 75 Ah prismatic cell could be used to make a 72,6 kWh battery for the Volkswagen e-Golf, a 56,1 kWh battery for the Volkswagen e-up or a 26,1 kWh battery for the Toyota Prius PHV.

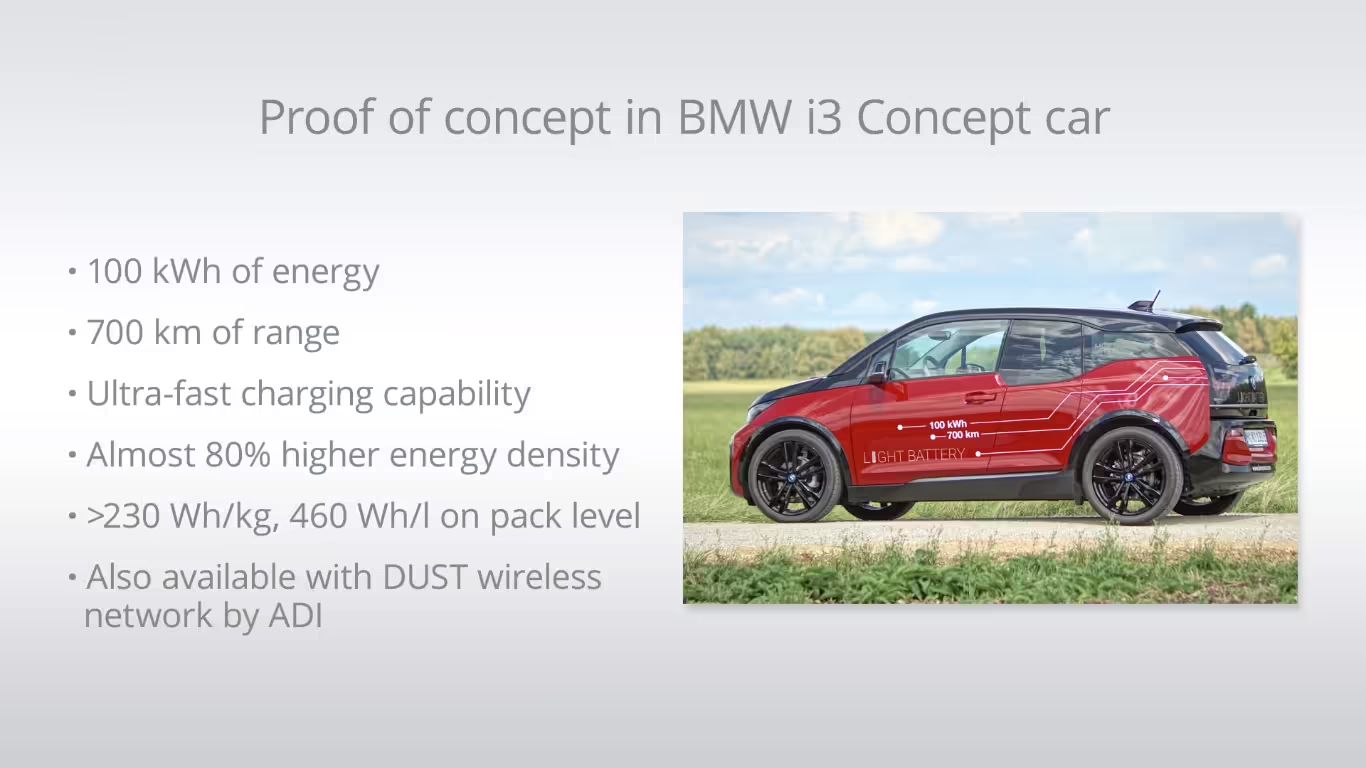

Summing up, when an energy density of 300 Wh/kg and a cost lower than 100 €/kWh are the minimum goals we can expect to see reached in two years, it’s obvious that ICE (Internal Combustion Engine) cars have their days numbered - sooner than many expected.

Furthermore it’s probable that before reaching 2020 even more impressive battery technology breakthroughs emerge as we’ve seen with the recent Sion Power announcement of 500 Wh/kg and 1.000 Wh/L.

It’s time for automakers to start investing resources to mass produce electric cars instead of trying to prove the impossible by gassing monkeys and humans, don’t you think?

More info:

http://cii-resource.com/cet/AABE-03-17/Presentations/BATO/Tao_Liang.pdf

https://pubs.acs.org/doi/pdfplus/10.1021/acsenergylett.7b00407