Starting this month - with the new 35,8 kWh battery for the 2017 Volkswagen e-Golf - Volkswagen will begin to use Samsung SDI as its supplier for battery cells.

This means that Panasonic/Sanyo loses a big customer for their battery cells, but it doesn’t seem that important since Tesla and now Toyota - with the Prius Prime - will keep the demand high.

As a side note, I’ve to say that in my previous articles I wrongly assumed that Volkswagen would keep Panasonic/Sanyo as its battery cell supplier and I’ve to thank Grendizer for the heads up.

Moving on…

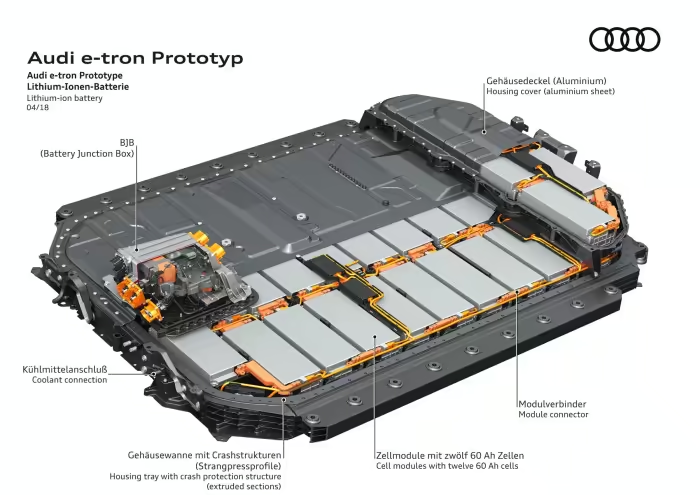

In the photo below we can see the Samsung SDI 37 Ah battery cell that will be used to build Volkswagen Group (Volkswagen, Audi and Porsche) battery packs.

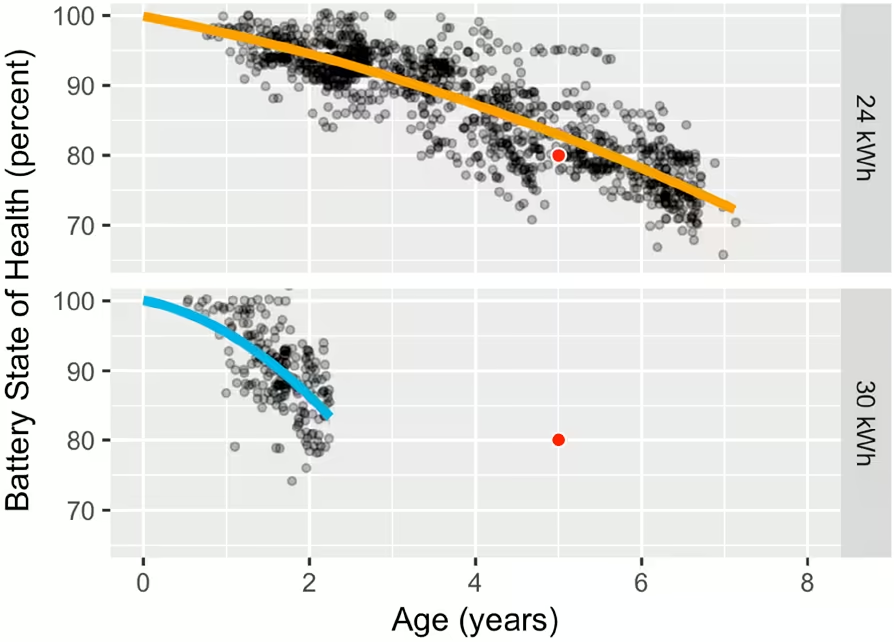

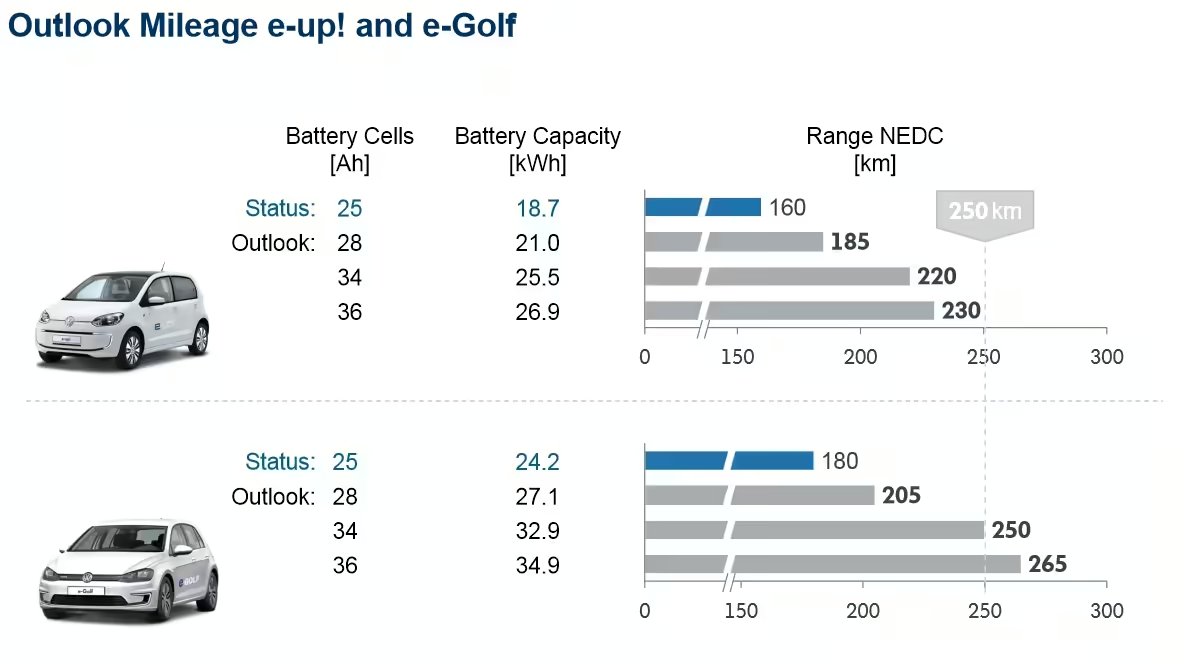

To better understand why Volkswagen changed its battery cell supplier, let’s see the Volkswagen roadmap for battery upgrades in the below. It shows us what Volkswagen and Panasonic/Sanyo had planned in 2014.

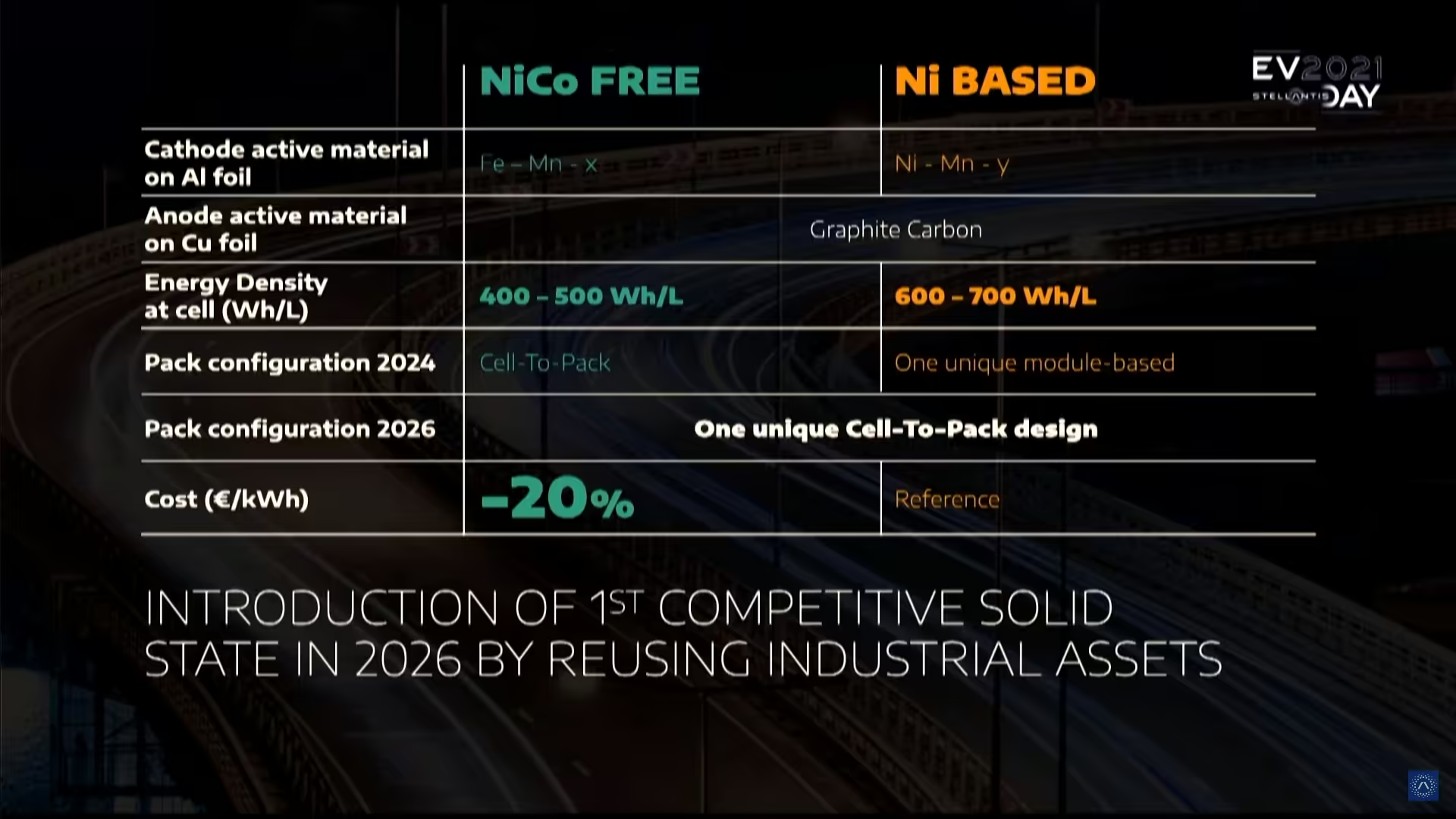

Samsung SDI realized they could do better and developed the 37 Ah battery cell that can directly replace the old 25 Ah made by Panasonic/Sanyo. This demonstrates the dedication of Samsung SDI to get more automakers as its customers. These 37 Ah battery cells and the ones they are replacing share one common characteristic. They have the high energy density required for BEVs (Battery Electric Vehicles) and the high power density that’s required for PHEVs (Plug-in Hybrid Electric Vehicles).

The Samsung SDI 37 Ah battery cells will also be used in BMW plug-in hybrid cars - which will get battery capacity upgrades this year.

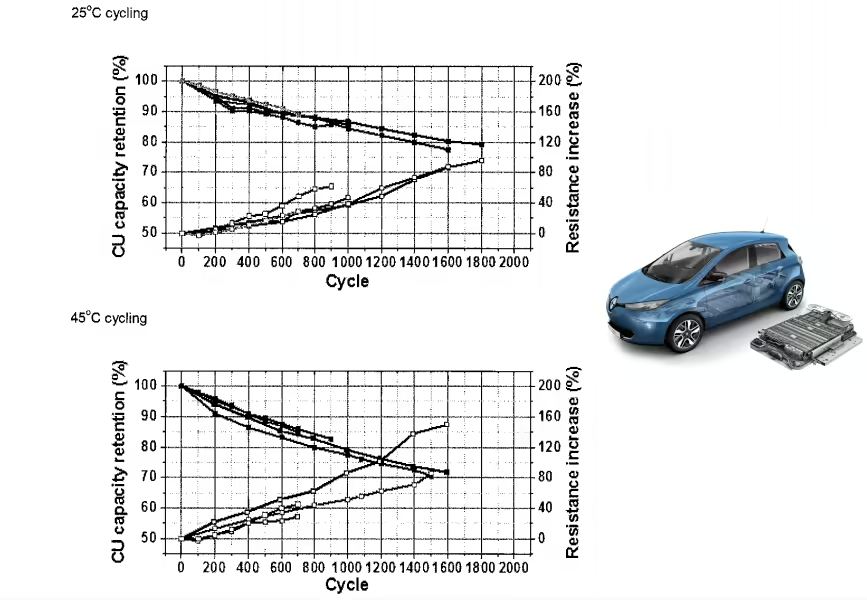

To sum up, it’s great to see Samsung SDI with two major automakers as clients (BMW and Volkswagen), with Mercedes joining the list later with the EQ sub-brand. The bad news for Samsung SDI is that the German automakers are still dragging their feets to build electric cars. This is why the Samsung SDI battery cell plant in Europe (Hungary) will only start operating in 2018 with an annual capacity to supply 50.000 EV batteries. This highly contrasts with the Renault-Nissan-Mitsubishi Alliance’s battery supplier (LG Chem) plans for Europe. LG Chem battery plant in Poland will start operating already this year with an annual production capacity of 100.000 EV batteries. In this aspect, LG Chem is in much better position as the Alliance’s battery cell supplier and Panasonic also is very comfortable with Tesla and Toyota in its customers list.

More info: