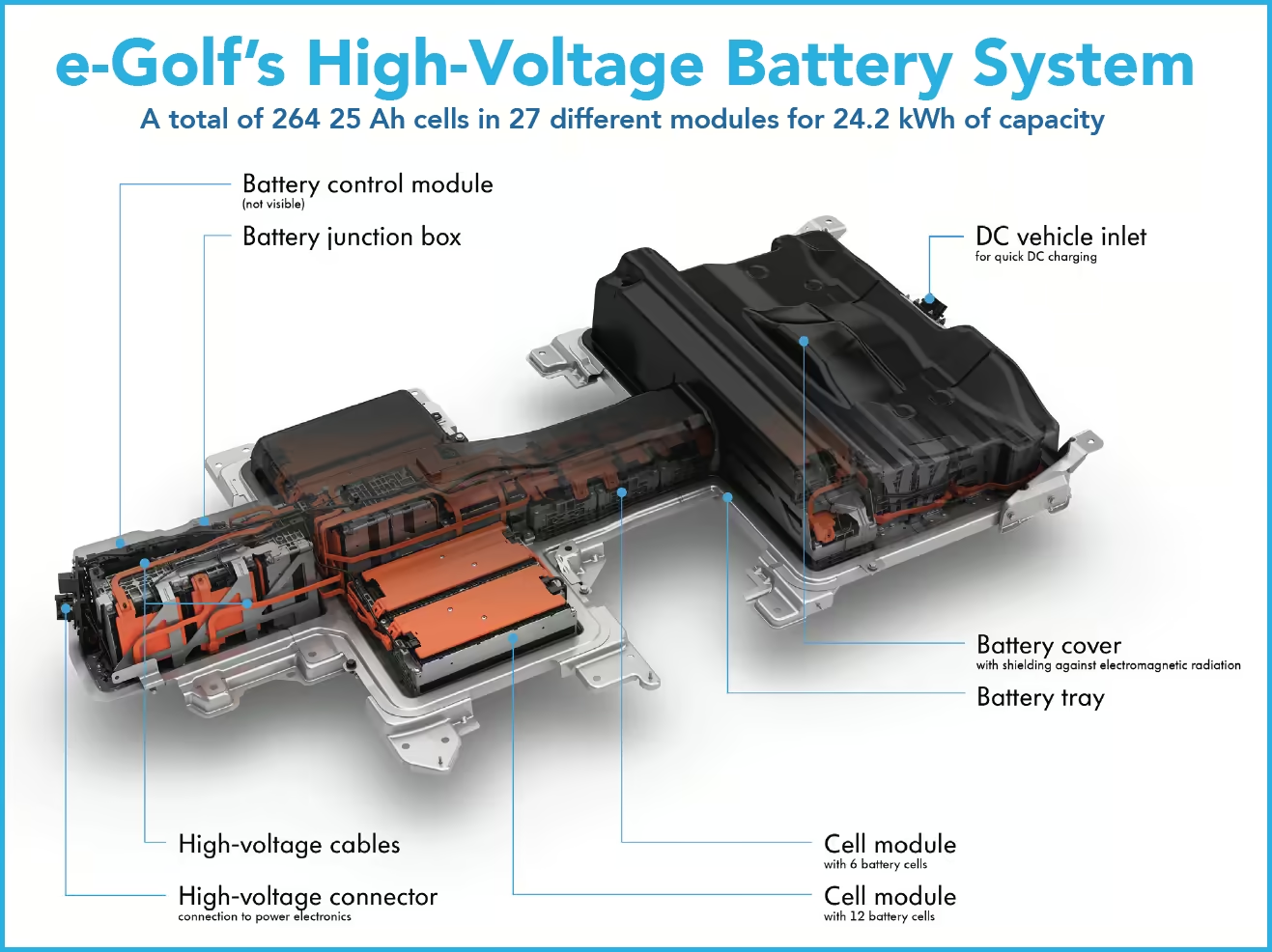

Volkswagen’s strategy for batteries could be resumed to using the same cells for BEVs and PHEVs. It has its pros and cons. But we’ll look into it ahead.

Volkswagen currently uses 25 Ah NMC cells made by Sanyo (owned by Panasonic) to make the batteries for its BEVs and PHEVs.

While it’s not easy to find simple information like weight and volume of these cells, Joachim from endless-sphere.com forum got some units and we now have some data.

- Weight: 724 g

- Dimensions: 14,7 x 9 x 2,5 cm

- Volume: 0,33075 L

- Nominal capacity: 25 Ah

- Nominal voltage: 3,667 V

- Volumetric energy density: 277 Wh/L

- Gravimetric energy density: 126 Wh/kg

But these 25 Ah cells are about to be replaced.

In January 2017 Volkswagen will start replacing the 25 Ah Panasonic/Sanyo cells with 37 Ah Samsung SDI cells.

Nevertheless even the new cells have average energy density, not great, because they are a compromise.

Usually automakers use different cells for BEVs and PHEVs, cells with more energy density are used in BEVs and cells with more power density are used in PHEVs. Volkswagen is the exception, the automaker uses the same cells for BEVs and PHEVs. This means that the cell’s characteristics are a compromise between energy and power density. The cells will never have an energy density nor a power density as good as they could, this is the biggest disadvantage of this strategy.

But there are a lot of advantages.

Using the same kind of cell in every plugin car allows Volkswagen to use volume to negotiate prices with the cell maker.

The cell maker can focus on just one kind of cell, maximizing resources for R&D (Research and Development) and minimizing production costs by requiring less machinery.

It makes battery upgrades easier. When a new higher capacity cell is introduced it can easily be used in every Volkswagen plugin car. This is what will happen with the introduction of the 37 Ah cell to every BEV and PHEV made by the Volkswagen Group.

In 2017 Volkswagen will surely have one of the lowest costs per kWh, certainly below 140 €.

These are the plugin cars of the Volkswagen Group that will use the 37 Ah cells:

- Volkswagen e-Golf

- Volkswagen e-up

- Volkswagen Golf GTE

- Volkswagen Passat GTE

- Audi A3 e-tron

- Audi Q7 e-Tron

- Porsche Cayenne S E-Hybrid

- Porsche Panamera 4 E-Hybrid

The third party battery maker, Kreisel Electric also uses only one type of cell to make its modules. In this case 18650 cylindrical cells. This makes replacing the cell supplier or start using a new more energy dense cell a lot easier.

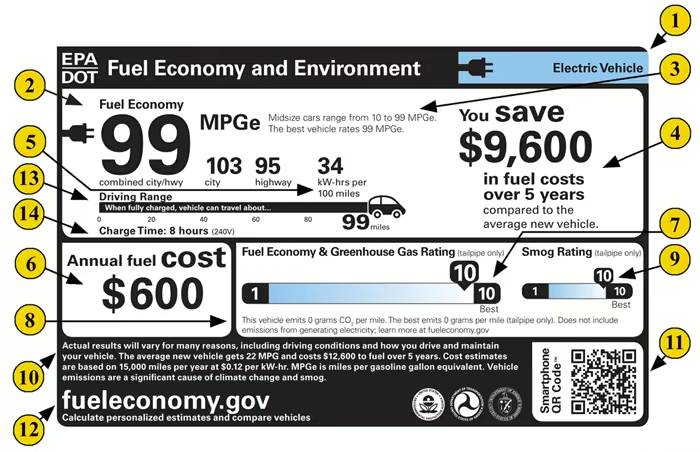

The same applies to Tesla Motors, that always use the same tiny cells in every electric car battery they make. But in Tesla Motors and Kreisel Electric cases, they only make batteries for BEVs, so they don’t need to compromise both power and energy densities. They clearly favor energy density.

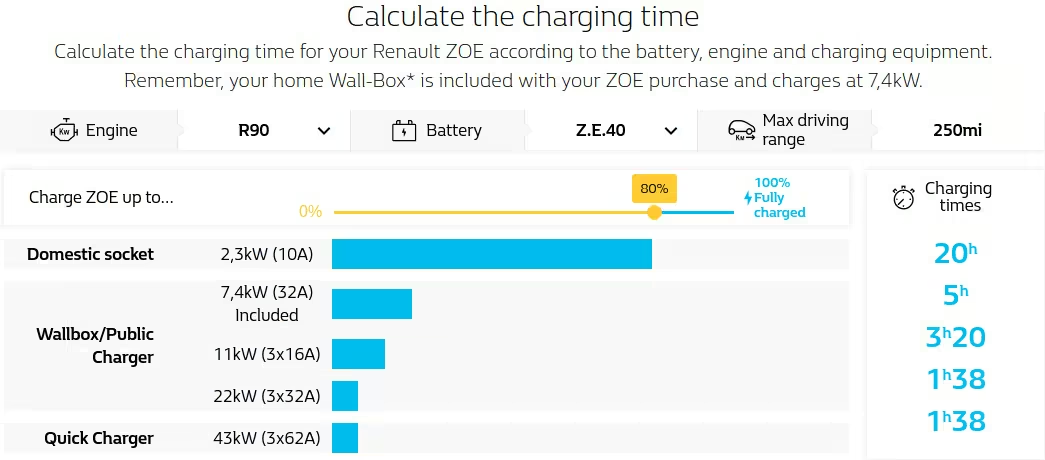

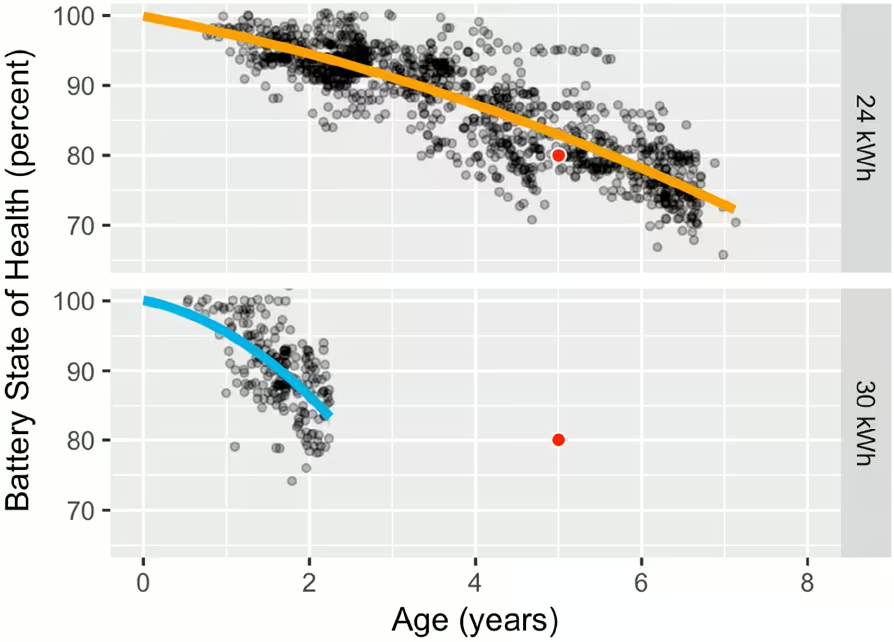

In this field the Renault-Nissan Alliance can do a lot more to reduce costs. Sharing the same cells for Zoe’s and Leaf’s batteries should be already happening, but I guess we’ll have to wait for the 43 kWh LG Chem batteries for it to finally happen.

Update: this article was revised because I wrongly assumed that the new 37 Ah battery cells would be made by Volkswagen’s current supplier (Panasonic/Sanyo), but instead, these new cells are made by Samsung SDI.

More info:

https://endless-sphere.com/forums/viewtopic.php?f=14&t=79639